Heating Equipment

Sinton, a proxy designation for a wide-ranging consortium of enterprises, encompassing those focused on thermal solutions, measurement, and control technologies, presents an extensive array of products and services. These encompass sophisticated heating elements and systems engineered for accurate temperature regulation to technical support and bespoke engineering solutions intended for the enhancement of industrial processes.

The focus is placed on the pivotal role played by these Sinton products in the efficient functionality of heating systems within industrial environments. They deliver localized, precise heating essential for various applications, including, but not limited to, the warming of metal components, process heating, and the temperature regulation of crucial parts in manufacturing and production lines.

Sinton's contributions stand out particularly in the realms of:

·Customizability: Proposing solutions that are adaptable to the specific requisites of an application, guaranteeing good performance.

·Efficiency: Accentuating products crafted for heightened efficiency, which can precipitate considerable energy savings and diminished operational expenses.

·Reliability: Guaranteeing the robustness and longevity of heating systems, pivotal for the sustenance of uninterrupted industrial processes. Technical Support: Supplying exhaustive support and resources, like technical libraries, CAD drawings, and engineering tools, to aid in the formulation and execution of efficacious heating solutions.

details

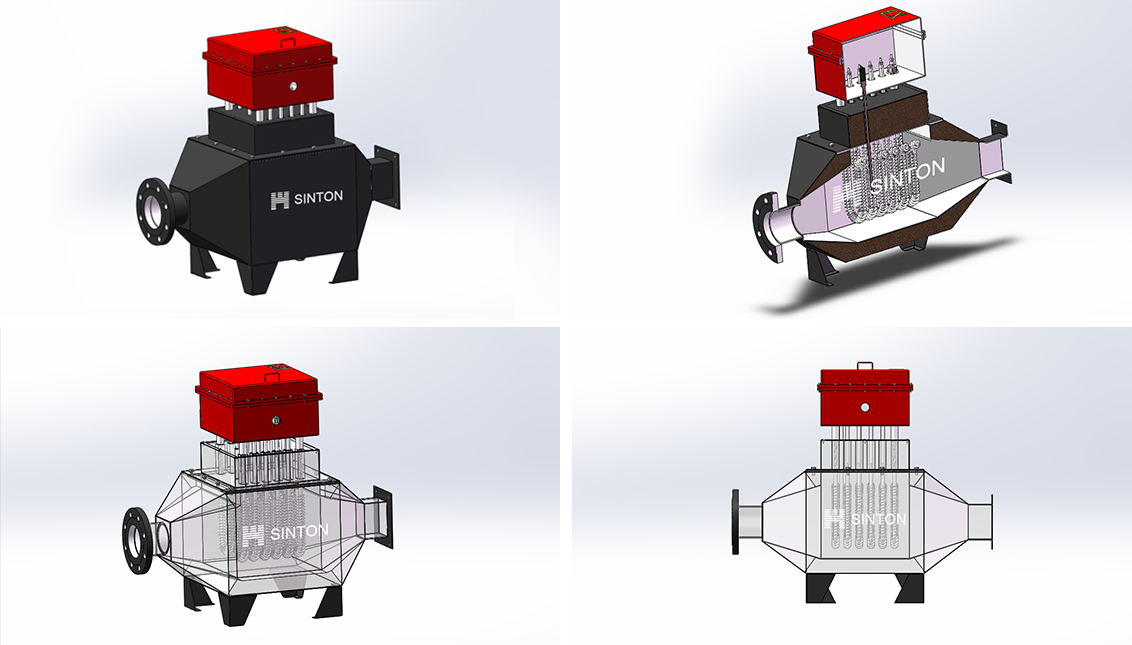

XTDQ-FD-15 Industrial Cotton Drying Hot Air Circulation Duct Heater is an efficient drying equipment specially designed for the textile industry. It is mainly used for fast and even drying of cotton, yarn, cloth and other textiles.

This equipment uses high-efficiency electric heating elements, which can generate a large amount of heat in a short period of time, quickly increase the temperature of the drying room, and ensure that cotton and other textiles are dried quickly and evenly. At the same time, the built-in hot air circulation system uses forced convection to continuously circulate hot air in the drying chamber, effectively avoiding heat loss and improving drying efficiency. This design ensures that textiles are heated evenly during the drying process and avoids local overheating or overcooling.

In order to meet the individual needs of users, XTDQ-FD-15 is equipped with an intelligent temperature control system. Users can set the drying temperature according to actual conditions, and the equipment will automatically adjust the output power to keep the temperature in the drying room constant. This design not only improves user convenience, but also saves energy and reduces energy waste.

In addition to its high efficiency and intelligent design, XTDQ-FD-15 also uses advanced electro-thermal conversion technology to achieve high energy utilization, thereby reducing energy waste. At the same time, there is no pollutant emission during the operation of the equipment, which meets environmental protection requirements and provides users with a green and environmentally friendly experience.

Product Parameter

| Model | Power | Inner Chamber size | Diameter of air outlet |

| KW | MM | MM | |

| FD-10 | 10 | 300*300*300 | DN100 |

| FD-20 | 20 | 500*300*300 | DN200 |

| FD-30 | 30 | 400*400*400 | DN300 |

| FD-40 | 40 | 500*400*400 | DN300 |

| FD-50 | 50 | 600*400*400 | DN350 |

| FD-60 | 60 | 700*400*400 | DN350 |

| FD-80 | 80 | 700*400*500 | DN350 |

| FD-100 | 100 | 900*400*500 | DN350 |

| FD-120 | 120 | 1000*400*500 | DN350 |

| FD-150 | 150 | 700*750*500 | DN400 |

| FD-180 | 180 | 800*750*500 | DN400 |

| FD-240 | 240 | 1000*750*600 | DN500 |

| FD-300 | 300 | 1200*750*600 | DN500 |

| FD-360 | 360 | 1000*800*900 | DN500 |

| FD-420 | 420 | 1200*800*900 | DN500 |

| FD-480 | 480 | 1400*800*900 | DN500 |

| FD-600 | 600 | 1600*1000*1000 | DN600 |

| FD-800 | 800 | 1800*1000*1000 | DN600 |

| FD-1000 | 1000 | 2000*1000*1000 | DN600 |

details

details

The versatility of Sinton air duct heaters allows for their application across multiple industrial uses, notably:

·Heating processes within manufacturing setups

·Air pre-heating in HVAC systems for sizable industrial edifices

·Drying and curing operations in the pharmaceutical, food, and painting sectors

·Chemical processing that necessitates exact temperature regulation

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE