Heating Equipment

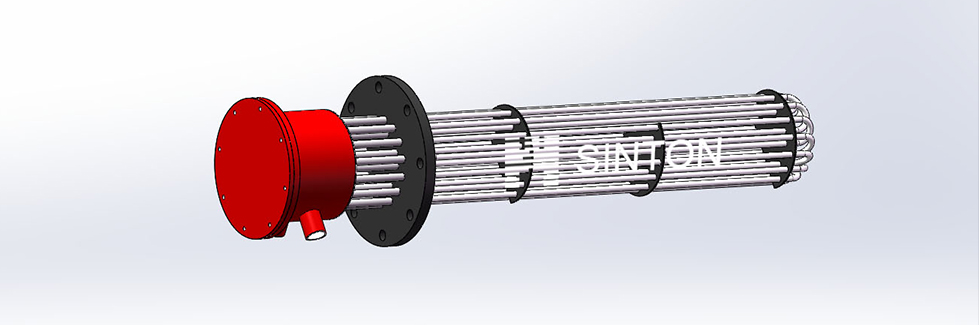

Sinton Pipeline Heaters are engineered with precision for efficient fitting within standard 2 or 3-inch schedule 40 NPS pipes.

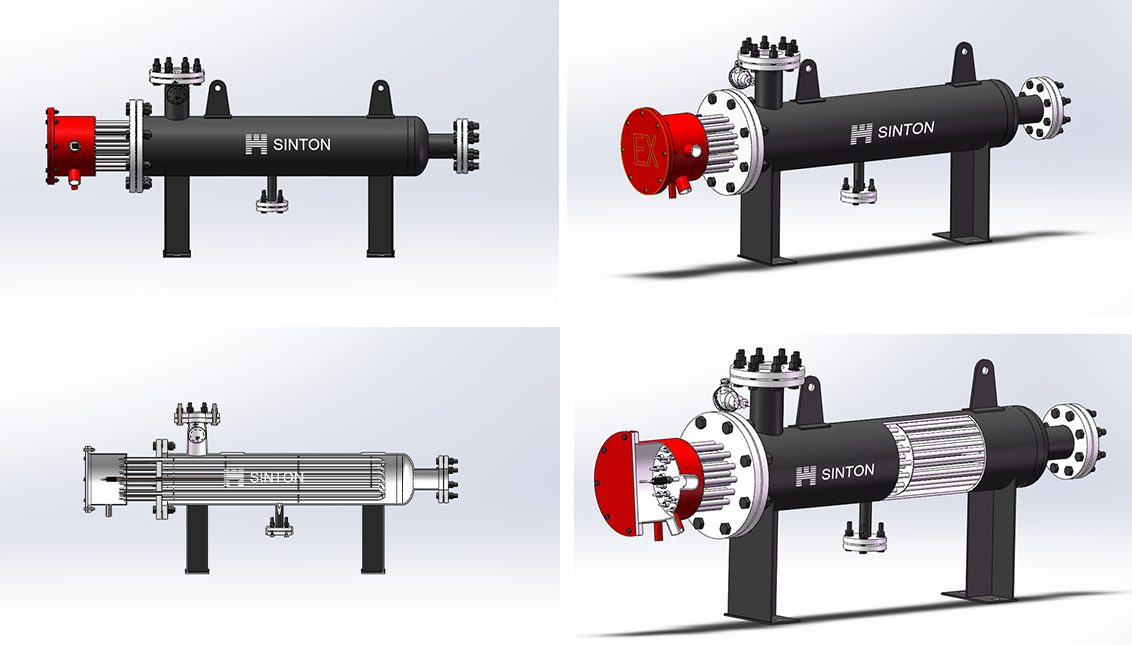

These are ideally suitable for tanks requiring very low watt densities and are suitable for waxes, thick liquids like tar and molasses, and corrosive mediums. All things considered, the heating elements of these heaters should not come into direct contact with the medium, hence making them easy to maintain and replaceable even without the tank being drained.

They are suitable for high heat environments and good for heavy bunker fuel oils, corrosive liquids, and high viscosity liquids.

details

The vertical pipeline heater is an electric heating device that is installed with a heating tube in a cylindrical heat preservation container to heat the gas. The pipe heater has the characteristics of fast heating speed, good heat preservation performance and high heating temperature. The vertical pipeline heater consists of two parts: the body and the control system. The heating element is made of stainless steel pipe as protective casing, high temperature resistance alloy wire, crystallized magnesium oxide powder, and formed by compression process. The control part adopts advanced digital circuit, integrated circuit trigger, high reverse voltage thyristor, etc. to form an adjustable temperature measurement and constant temperature system, which ensures the normal operation of the electric heater.

Product Parameter

| Specifications | Power | Pipeline heater(liquid) | Pipeline heater(gas) | ||

| KW | Heating room size(mm) | Connection diameter(mm) | Heating room size(mm) | Connection diameter(mm) | |

| XTGD-5 | 5 | DN80*500 | DN25 | DN100*600 | DN25 |

| XTGD-10 | 10 | DN80*700 | DN32 | DN100*700 | DN32 |

| XTGD-15 | 15 | DN125*700 | DN32 | DN125*700 | DN32 |

| XTGD-20 | 20 | DN150*800 | DN40 | DN150*900 | DN40 |

| XTGD-30 | 30 | DN150*800 | DN40 | DN150*1000 | DN40 |

| XTGD-40 | 40 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-50 | 50 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-60 | 60 | DN200*1200 | DN50 | DN250*1300 | DN80 |

| XTGD-80 | 80 | DN250*1400 | DN80 | DN250*1500 | DN80 |

| XTGD-100 | 100 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-120 | 120 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-150 | 150 | DN300*1600 | DN100 | DN350*1600 | DN125 |

| XTGD-180 | 180 | DN300*1600 | DN100 | DN350*1800 | DN125 |

| XTGD-200 | 200 | DN300*1800 | DN100 | DN400*1800 | DN150 |

| XTGD-240 | 240 | DN350*1800 | DN125 | 2*DN300*1600 | DN150 |

| XTGD-280 | 280 | DN350*1800 | DN125 | 2*DN350*1600 | DN150 |

| XTGD-300 | 300 | DN400*1800 | DN150 | 2*DN350*1600 | DN150 |

| XTGD-360 | 360 | DN400*1800 | DN150 | 2*DN350*1800 | DN150 |

| XTGD-400 | 400 | 2*DN300*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-450 | 450 | 2*DN350*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-500 | 500 | 2*DN350*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-600 | 600 | 2*DN400*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-700 | 700 | 2*DN400*1800 | DN150 | 2*DN500*1800 | DN150 |

| XTGD-800 | 800 | 4*DN300*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-900 | 900 | 4*DN350*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-1000 | 1000 | 4*DN350*1800 | DN150 | 4*DN450*1800 | DN150 |

details

Vertical pipeline heater advantages:

1. The vertical pipeline heater adopts a stainless steel cylinder, which is small in size, occupies less land, and is easy to move. A thickened insulation layer is used between the stainless steel inner tank and the stainless steel outer shell, which has a low degree of temperature loss, maintains temperature, and saves electricity.

2. The main parts of the heating element (stainless steel electric heating tube) are made of imported materials, and the processing process also uses advanced production equipment and technology, and cooperates with different voltages to exert high performance.

3. Reasonable flow direction design, uniform heating, no high and low temperature dead angle, high thermal efficiency

4. The vertical pipeline heater is equipped with a well-known domestic brand thermostat, and users can freely set the temperature. All are equipped with overheating protectors, which are used to control temperature and protect against water shortage and overtemperature, so as to avoid damage to heating elements and systems.

Features of Vertical Pipeline Heater:

1. Vertical pipe heater occupies a small area but has a requirement for height, while the horizontal type occupies a large area but does not require height.

2. Vertical pipe heater materials are: carbon steel, stainless steel SUS304, stainless steel SUS316L, SUS 310S ect. Choose suitable materials according to different heating requirements.

3. The vertical pipeline heater adopts flange heat, and is equipped with a professionally designed deflector to ensure that the electric heating tube heats up evenly and the heating medium fully absorbs heat.

4. Temperature requirements (the temperature of the air outlet is greater than 6 It is heated by stainless steel 310S electric radiation heating tube, and the temperature of the gas outlet can reach 800°C.

details

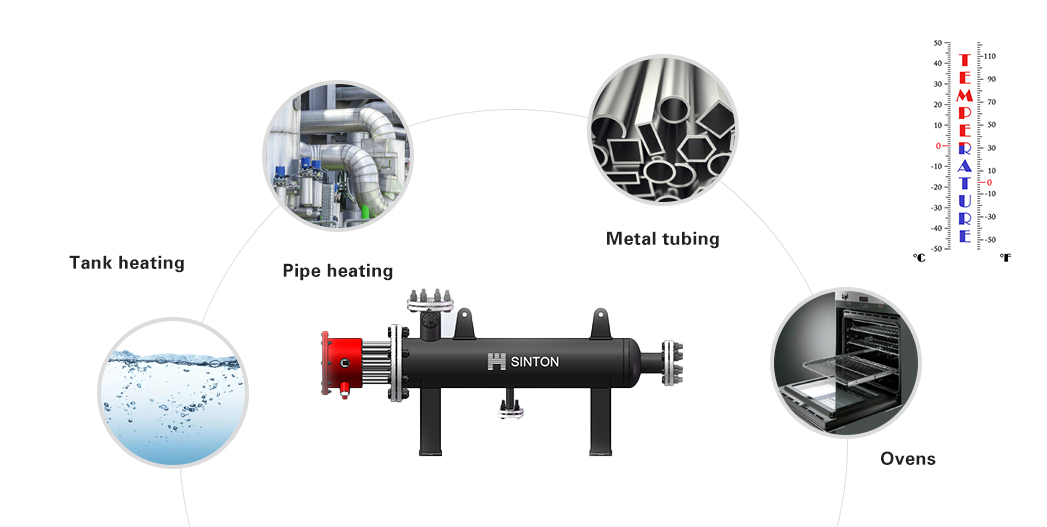

The Sinton Pipeline Heaters are so versatile in their applications that they can be used for:

They are designed for oil, gas, food processing, and power production industries to provide efficient solutions in heating through a wide spectrum of applications.

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE