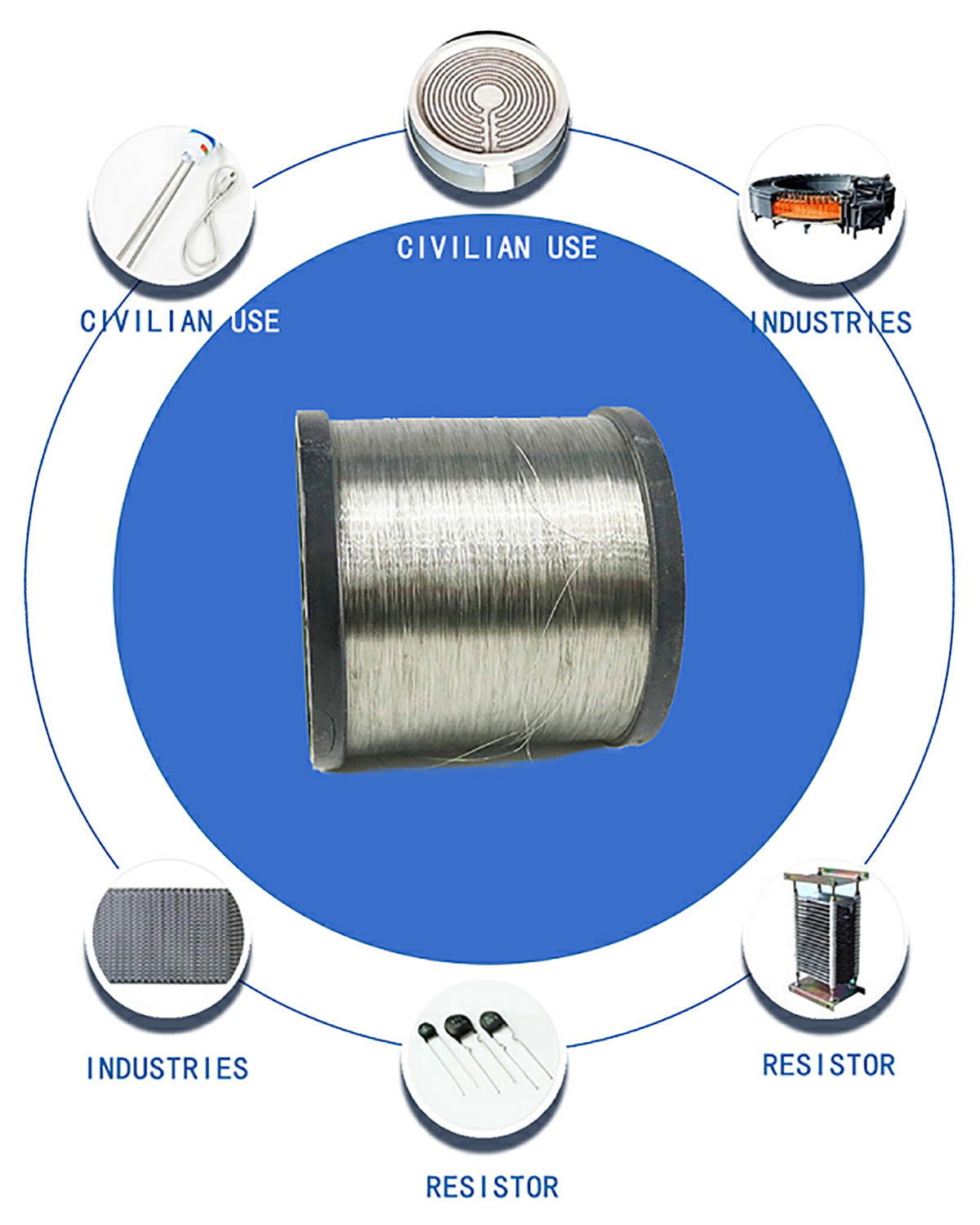

Heating Equipment

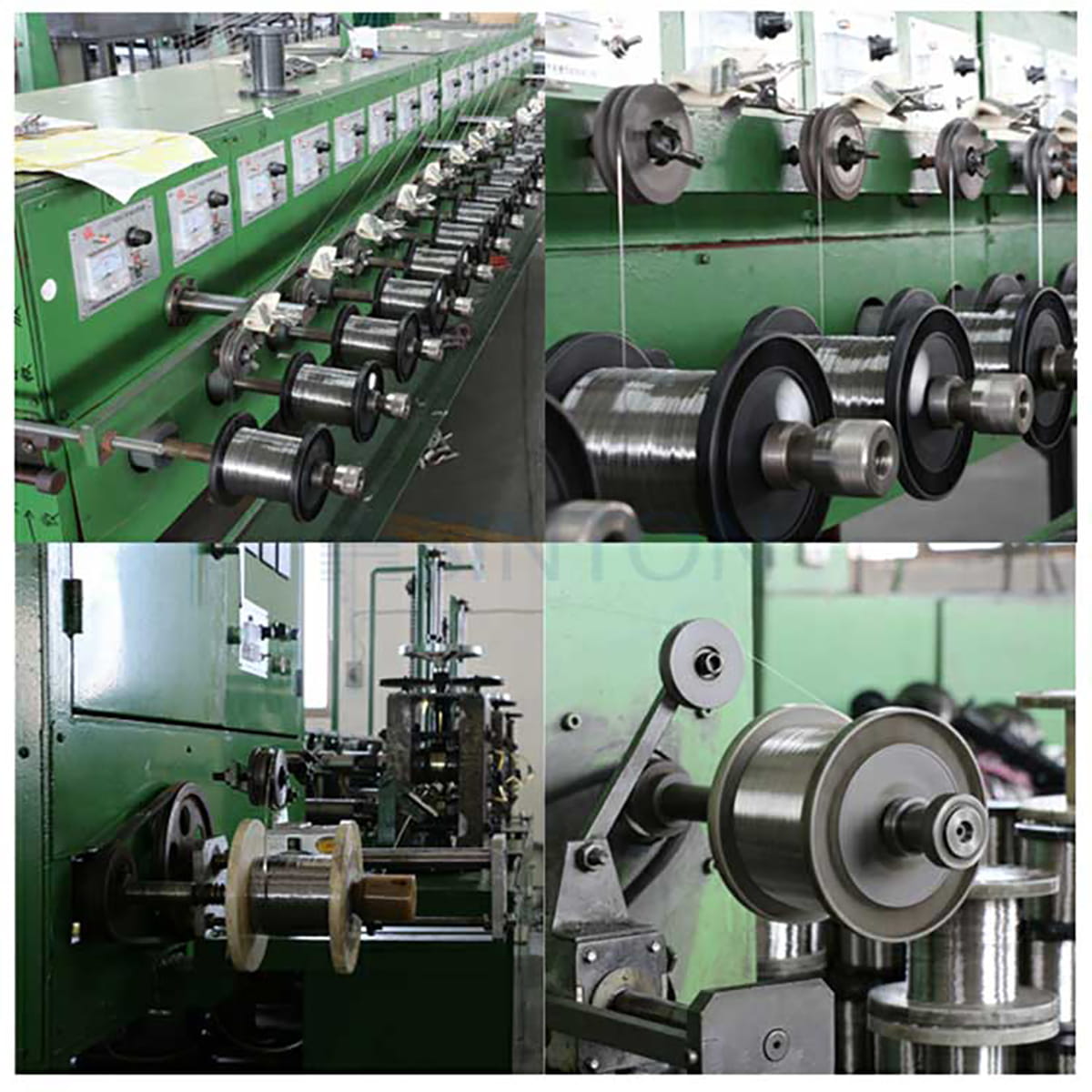

details

Product Parameter

| Alloy Nomenclature Performance | Cr20Ni80 | Cr30N170 | Cr15Ni60 | Cr20Ni35 | Cr20N130 | |

| Main Chemical composition | Ni | Rest | Rest | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Max.continuous service temp.of element(℃) | 1200 | 1250 | 1150 | 100 | 110 | |

| Resistivity at 20oC (μΩ·m) | 1.09 | 1.18 | 1.12 | 1.0 | 1.04 | |

| Density(g/cm3) | 8.40 | 8.10 | 8.20 | 7.90 | 7.90 | |

| Thermal conductivity (KJ/m·h·℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion(a×10-6/℃) | 18.0 | 17.0 | 17.0 | 19.0 | 19.0 | |

| Melting point approx.(℃) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation at rupture(%) | >20 | >20 | >20 | 20 | >20 | |

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties |

Nonmagnetic |

Nonmagnetic |

Weak magnetic | Weak magnetic | Weak magnetic | |

details

details

Shipment

provides customers with quality and safe transportation.

Temperature Control Mechanisms in Explosion Proof Oil Circulation HeatersThe temperature control in Explosion Proof Oil Circulation Heaters is a critical comp...

READ MORE1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MORE