Heating Equipment

Resistance Wire is a specialized type of wire designed to resist the flow of electric current, converting electrical energy into heat. This wire is typically used in various heating applications due to its high electrical resistance and ability to generate heat when an electric current passes through it. Commonly used in heating elements for industrial, commercial, and residential purposes, resistance wire is an essential component in products like electric heaters, toasters, ovens, and industrial furnaces.

What is Resistance Wire?

Resistance wire is typically made from alloy materials that possess high resistivity, such as nichrome (nickel-chromium alloy), kanthal (iron-chromium-aluminum alloy), or copper-nickel alloys. The wire’s resistance to electrical flow causes it to heat up, which is the fundamental principle behind many heating elements in electrical appliances and industrial machinery. The wire is carefully engineered to handle specific amounts of current and heat generation, making it an ideal choice for creating reliable and durable heating elements.

High Electrical Resistance:

The primary feature of resistance wire is its ability to resist the flow of electricity, which results in the conversion of electrical energy into heat. This makes it ideal for use in heating elements and devices that require precise temperature control.

Durable and Long-Lasting:

Made from high-quality alloys, resistance wire is designed to withstand high temperatures, making it highly durable in harsh environments. It can perform reliably even under continuous high-heat conditions.

High-Temperature Tolerance:

Resistance wires are specifically designed to withstand high temperatures without breaking down or losing functionality. The wire maintains its integrity and performance even in extreme heat, which makes it a critical material for industrial heating applications.

Variety of Alloys:

Common alloys used in resistance wire include:

Nichrome (NiCr): Popular in high-temperature applications like electric furnaces, toasters, and hair dryers.

Kanthal (FeCrAl): Known for high-temperature stability, often used in industrial and laboratory heating applications.

Copper-Nickel Alloys: Often used in low to medium temperature heating elements and for applications requiring good electrical conductivity.

Customizable:

Resistance wire can be customized in terms of diameter, length, and material composition to meet specific needs in various heating applications. This flexibility makes it a versatile choice for different industries.

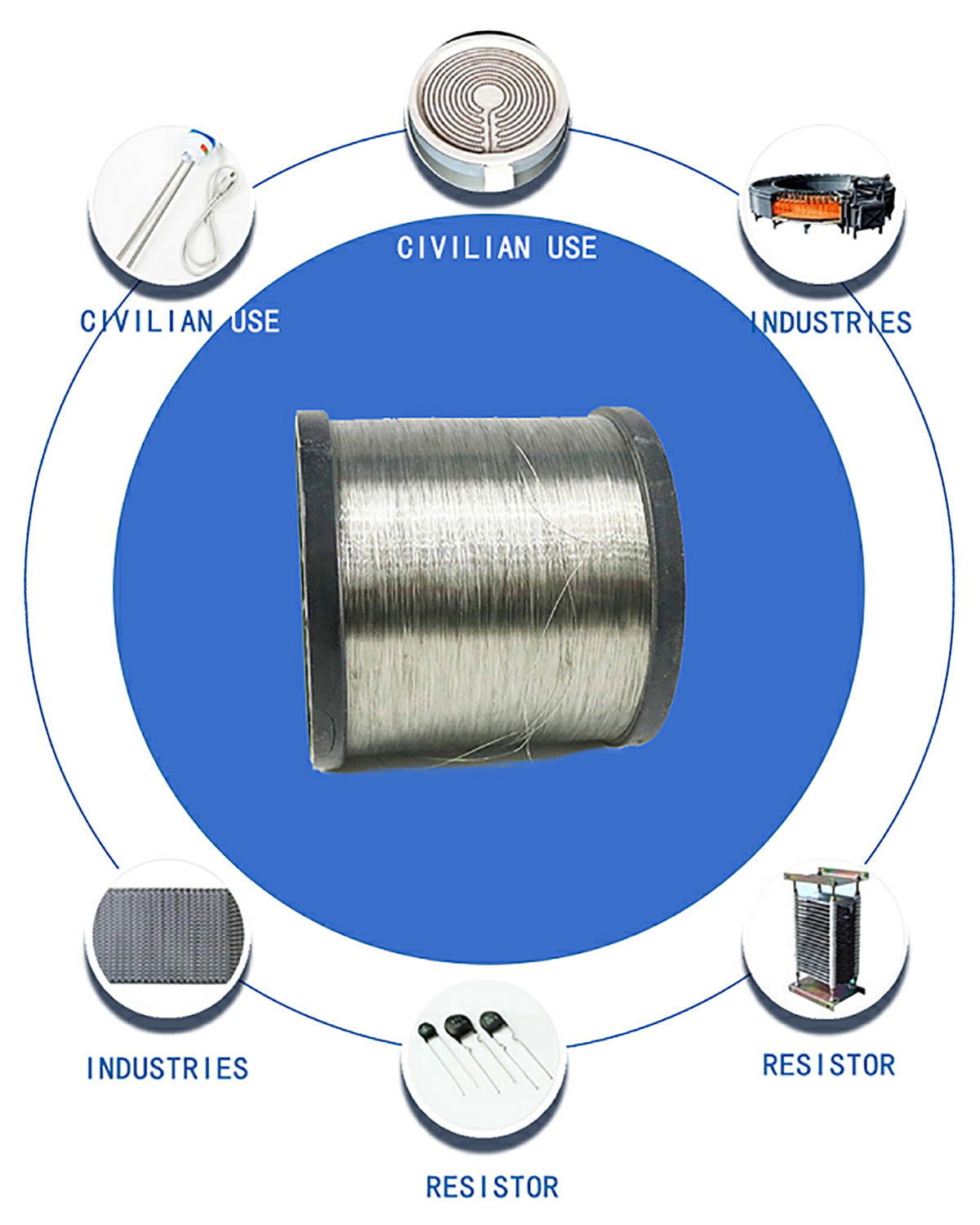

Heating Elements:

Electric Heaters: Used in space heaters, water heaters, and radiators, resistance wire provides the heat necessary for these devices to warm air or liquids.

Ovens and Toasters: Resistance wire is commonly used in the heating elements of kitchen appliances, where high-temperature heating is needed to cook or toast food.

Industrial Furnaces:

In industrial heating applications, resistance wire is employed in furnaces, kilns, and annealing ovens. The wire’s ability to maintain high heat levels is critical for processes such as metal heating, glass production, and ceramics firing.

Soldering Irons:

Soldering irons and other electronic tools use resistance wire as a heating element to generate the precise temperature needed for melting solder and creating strong electrical connections in electronics.

Temperature Sensors:

Resistance wire is used in certain temperature sensors and thermistors, as its resistance changes with temperature, providing accurate readings for temperature control and monitoring systems.

Electric Blankets and Clothing:

In consumer products like electric blankets and heated clothing, resistance wire is used to generate gentle, consistent heat, ensuring comfort and warmth without overheating.

Automotive Applications:

Resistance wire is found in car seat heaters, defroster systems, and other automotive components requiring controlled heating to enhance comfort or functionality.

· Efficient Heat Generation: The wire efficiently converts electrical energy into heat, making it ideal for heating applications across a wide range of industries.

· Durability: Made from high-strength alloys, resistance wire is designed to withstand extreme heat without degradation, ensuring long-term reliability.

· High-Temperature Capability: Resistance wire can handle extremely high temperatures without compromising its performance, making it suitable for industrial furnaces and heavy-duty heating systems.

· Customizable for Specific Applications: Available in a variety of materials and sizes, resistance wire can be tailored to meet specific heating needs in industries like automotive, electronics, and plastics.

Cost-Effective: Resistance wire is a cost-efficient solution for a wide range of heating applications due to its ability to generate significant heat at relatively low material costs.

details

Product Parameter

| Alloy Nomenclature Performance | Cr20Ni80 | Cr30N170 | Cr15Ni60 | Cr20Ni35 | Cr20N130 | |

| Main Chemical composition | Ni | Rest | Rest | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Max.continuous service temp.of element(℃) | 1200 | 1250 | 1150 | 100 | 110 | |

| Resistivity at 20oC (μΩ·m) | 1.09 | 1.18 | 1.12 | 1.0 | 1.04 | |

| Density(g/cm3) | 8.40 | 8.10 | 8.20 | 7.90 | 7.90 | |

| Thermal conductivity (KJ/m·h·℃) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion(a×10-6/℃) | 18.0 | 17.0 | 17.0 | 19.0 | 19.0 | |

| Melting point approx.(℃) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Elongation at rupture(%) | >20 | >20 | >20 | 20 | >20 | |

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties |

Nonmagnetic |

Nonmagnetic |

Weak magnetic | Weak magnetic | Weak magnetic | |

details

details

Shipment

provides customers with quality and safe transportation.

Temperature Control Mechanisms in Explosion Proof Oil Circulation HeatersThe temperature control in Explosion Proof Oil Circulation Heaters is a critical comp...

READ MORE1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MORE