Heating Equipment

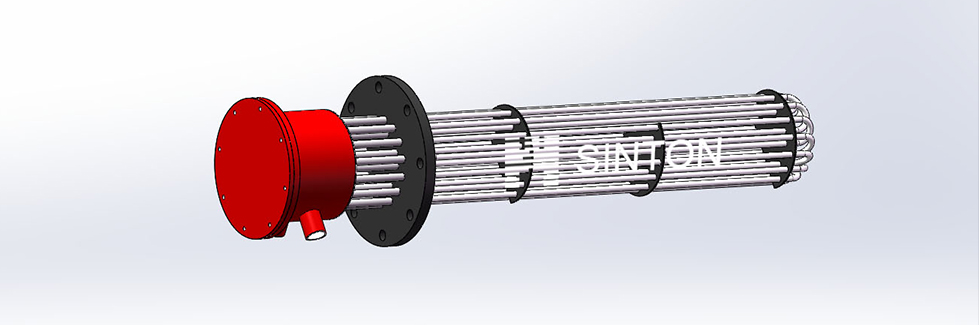

Sinton Pipeline Heaters are engineered with precision for efficient fitting within standard 2 or 3-inch schedule 40 NPS pipes.

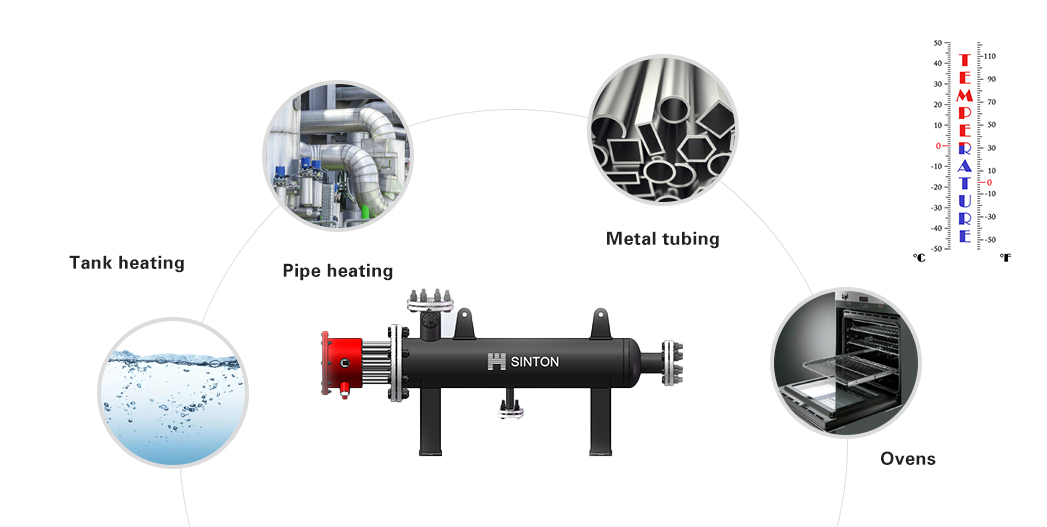

These are ideally suitable for tanks requiring very low watt densities and are suitable for waxes, thick liquids like tar and molasses, and corrosive mediums. All things considered, the heating elements of these heaters should not come into direct contact with the medium, hence making them easy to maintain and replaceable even without the tank being drained.

They are suitable for high heat environments and good for heavy bunker fuel oils, corrosive liquids, and high viscosity liquids.

details

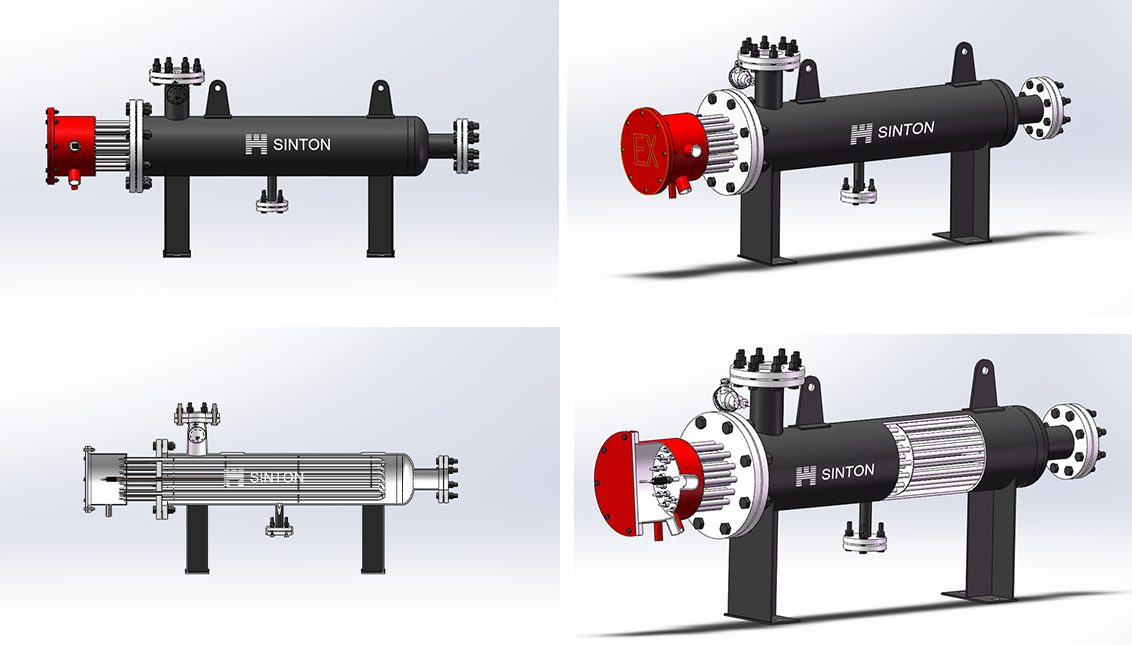

Industrial High Efficiency Explosion Proof Circulation Pipeline Liquid Heater uses advanced heating technology and materials to provide industrial users with efficient, safe and reliable heating solutions. The heater uses efficient electric heating elements and optimized heat exchange design, making the heating efficiency as high as over 95%, effectively reducing energy consumption. The electric heating element used has a low surface load and can quickly convert electrical energy into heat energy to avoid wastage of energy. At the same time, its optimized heat exchange design can maximize the use of heat energy and improve heating efficiency. Therefore, the heater has higher heating speed and lower energy consumption, saving a lot of energy costs for industrial users.

The product adopts special explosion-proof materials and structural design and complies with international explosion-proof standards to ensure the safety of use in hazardous environments. Its explosion-proof materials have good corrosion resistance and high temperature resistance, and can withstand harsh working environments. At the same time, its structural design has also been carefully designed to effectively prevent sparks and explosions and ensure workplace safety.

The heater has powerful circulation heating capabilities and uses professional circulation pump and pipeline design to ensure that the liquid in the pipeline is evenly heated and avoid local overheating or uneven temperature problems. Its circulation pump has a large flow rate and pressure, which can quickly circulate the liquid to ensure that the liquid fully contacts the heating tube to achieve a higher heating effect. At the same time, its pipeline design adopts multi-channel bending and resistance design, which can effectively reduce the flow rate of the liquid, ensure the time the liquid stays in the pipeline, and improve the heating efficiency.

Sinton provides the following options for customization in the pipeline heaters: The flange heaters can be used where the slip-on flanges are welded onto the tank, while the screw plug heater ensures a maintenance-free solution that screws into a coupling.

In a highly vibrating environment, however, a tubular element will be used, for its elements are rigid. Coiled heating elements are used in an area where efficient heat transfer and easy replacement are to be met in order to work within budgetary constraints.

Product Parameter

| Specifications | Power | Pipeline heater(liquid) | Pipeline heater(gas) | ||

| KW | Heating room size(mm) | Connection diameter(mm) | Heating room size(mm) | Connection diameter(mm) | |

| XTGD-5 | 5 | DN80*500 | DN25 | DN100*600 | DN25 |

| XTGD-10 | 10 | DN80*700 | DN32 | DN100*700 | DN32 |

| XTGD-15 | 15 | DN125*700 | DN32 | DN125*700 | DN32 |

| XTGD-20 | 20 | DN150*800 | DN40 | DN150*900 | DN40 |

| XTGD-30 | 30 | DN150*800 | DN40 | DN150*1000 | DN40 |

| XTGD-40 | 40 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-50 | 50 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-60 | 60 | DN200*1200 | DN50 | DN250*1300 | DN80 |

| XTGD-80 | 80 | DN250*1400 | DN80 | DN250*1500 | DN80 |

| XTGD-100 | 100 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-120 | 120 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-150 | 150 | DN300*1600 | DN100 | DN350*1600 | DN125 |

| XTGD-180 | 180 | DN300*1600 | DN100 | DN350*1800 | DN125 |

| XTGD-200 | 200 | DN300*1800 | DN100 | DN400*1800 | DN150 |

| XTGD-240 | 240 | DN350*1800 | DN125 | 2*DN300*1600 | DN150 |

| XTGD-280 | 280 | DN350*1800 | DN125 | 2*DN350*1600 | DN150 |

| XTGD-300 | 300 | DN400*1800 | DN150 | 2*DN350*1600 | DN150 |

| XTGD-360 | 360 | DN400*1800 | DN150 | 2*DN350*1800 | DN150 |

| XTGD-400 | 400 | 2*DN300*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-450 | 450 | 2*DN350*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-500 | 500 | 2*DN350*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-600 | 600 | 2*DN400*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-700 | 700 | 2*DN400*1800 | DN150 | 2*DN500*1800 | DN150 |

| XTGD-800 | 800 | 4*DN300*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-900 | 900 | 4*DN350*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-1000 | 1000 | 4*DN350*1800 | DN150 | 4*DN450*1800 | DN150 |

details

Sinton Pipeline Heaters short heat-up time, replacement, or easy set of features and benefits that include: more economical open coil elements to provide efficient heat transfer.

•Ceramic that has the ability to bear high thermal heat is mechanical support for coils.

• Compatibility of thermocouples for temperature regulation

• Use of steel pipes for their thermal and corrosion resisting property.

Sinton Pipeline Heaters are efficient with inline heaters (circjson heaters) directly immersed in the liquid to transfer electric power into heating the substance or element effectively. This is much more efficient than other sources of heating, losing the potential energy. Inline heaters are easy to install, maintain, and also can be transferred between applications; therefore, inline heaters are versatile in many industries. Pipeline Heaters - Process Skids: For applications at sites

details

The Sinton Pipeline Heaters are so versatile in their applications that they can be used for:

They are designed for oil, gas, food processing, and power production industries to provide efficient solutions in heating through a wide spectrum of applications.

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE