Heating Equipment

1.Electric Heating Principle

Resistance Heating: When an electric current passes through the resistance wire, heat is generated according to Joule's law. Then, the heat is transferred to the pipeline in a conduction manner through the insulating and heat-conducting material, thus increasing the temperature of the fluid inside the pipeline.

Electromagnetic Induction Heating: An alternating current is passed through the coil to generate an alternating magnetic field. This makes the pipeline generate an induced electromotive force. Heat is generated by utilizing the resistance of the pipeline itself. The heating power can be controlled precisely by changing parameters such as the number of turns of the coil and the magnitude of the current.

2.Steam Heating Principle

Steam flows inside the pipeline heater. The heat is transferred from the steam side to the fluid inside the pipeline through the pipeline wall in a conduction manner. After releasing heat, the steam condenses into water. A steam trap device is required to discharge the condensed water in a timely manner to prevent any impact on heating and the occurrence of water hammer.

3.Heat Transfer Oil Heating Principle

The heat transfer oil is heated in the heating furnace and then sent to the pipeline heater by a circulating pump. It exchanges heat with the fluid inside the pipeline. Due to its high specific heat capacity and good thermal stability, the heating power can be precisely controlled by adjusting the flow rate and temperature of the heat transfer oil.

4.Hot Air Heating Principle

The fan sends air into the heating device to form hot air. The hot air is then sent to the surroundings or inside of the pipeline to be heated through pipelines. The heat is transferred to the pipeline and the fluid inside it in a convection and radiation manner. It has the characteristics of fast heating and uniform temperature.

Parameters:

|

Material |

Stainless Steel |

|

Form |

Spiral Heating Element |

|

Shape |

Round |

|

Application |

Oil, Water |

|

Thermal Efficiency |

More Than 95% |

|

Dimension(L*W*H) |

Customized |

|

Max Temperature |

800 C |

|

Voltage |

220-480V |

|

Style |

Horizontal Type |

|

Transport Package |

Wooden Box |

|

Specification |

can be customized |

|

Trademark |

Cheri |

|

Origin |

China |

|

HS Code |

8516800000 |

|

Production Capacity |

500/Year |

Advantage:

1.Heating Efficiency

Fast heating: Electric - type heaters can heat pipeline fluids rapidly. Electromagnetic - induction ones work in minutes, much faster than traditional ones.

High efficiency: In heat - transfer - oil pipeline heaters, heat transfer is good, with low losses and over 90% efficiency, saving energy.

2.Temperature Control

Accurate: Heaters with advanced sensors and smart systems can control temperature within ±1℃ or better, keeping fluids stable for high - precision processes.

Even: All heating methods can evenly heat pipeline fluids through proper design, ensuring product quality.

3.Safety

Many safeguards: Equipped with over - temperature, over - pressure, and leakage protections, they cut power automatically in case of problems.

Safe by nature: Explosion - proof electric heaters prevent sparks in dangerous areas, ensuring safety.

Applications:

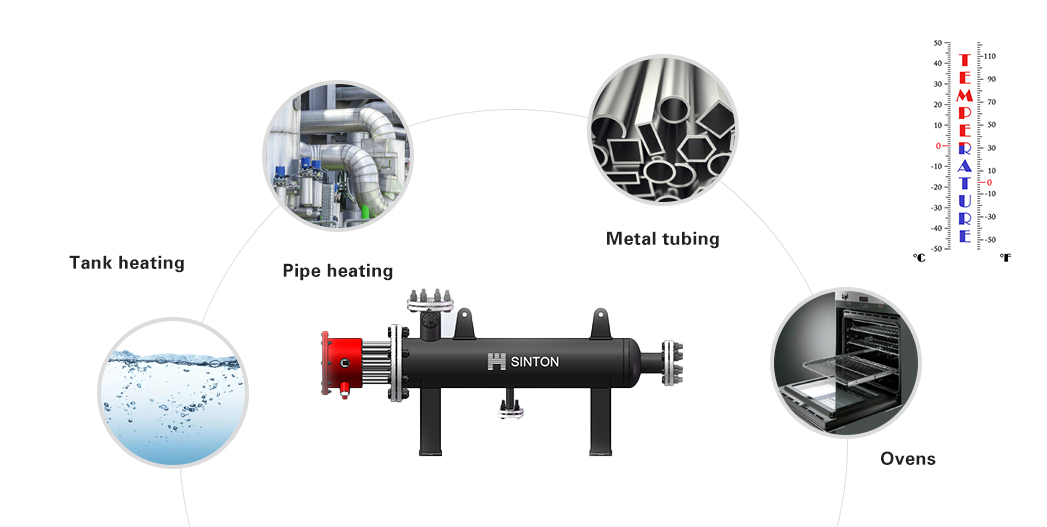

1.Petroleum and Chemical Industry: During the transportation of crude oil and chemical products, as well as in the production of polymers, they prevent materials from solidifying and crystallizing, ensuring their fluidity to meet the requirements of reactions and transportation.

2.Power Industry: Applied to steam pipelines, desulfurization and denitrification systems, and air cooling systems to maintain the temperature and ensure the power generation efficiency and stable operation of the systems.

3.Food and Beverage Industry: In the processes of material transportation, beer brewing, and edible oil production, they keep the materials at an appropriate temperature, facilitating subsequent processes.

4.Pharmaceutical Industry: Heat the pipelines for liquid medicine and raw material drugs transportation, ensuring the stability of the liquid medicine, its efficacy, and the production quality of raw material drugs.

5.HVAC (Heating, Ventilation, and Air Conditioning) Industry: Provide trace heating for the centralized hot water supply system and heat the air or refrigerant in the air conditioning system to meet the heating and temperature regulation requirements.

6.Marine Industry: Heat the pipelines of fuel oil and lubricating oil to reduce their viscosity and ensure the normal operation of engines and equipment.

7.Paper Industry: Heat the pipelines of pulp and coating liquid to prevent precipitation and caking, ensuring the continuity of production and the coating quality.

details

Industrial Electric Melt Blown Pipeline Heater is an advanced heating equipment specially designed for industrial production. It is widely used in pipeline heating and insulation in chemical, petroleum, pharmaceutical, food and other industries. It uses high-efficiency electrofusion technology and a unique purge design to quickly and evenly heat the fluid inside the pipeline to ensure the continuity and stability of the production process.

Through advanced electrofusion heating technology, this heater features high thermal efficiency and low energy consumption. Its high-efficiency thermal conductive material can quickly convert electrical energy into thermal energy, allowing the fluid in the pipeline to reach the required temperature in a short time, greatly reducing production costs.

The unique purge design is a highlight of this heater, which ensures that the fluid in the pipeline is heated evenly and avoids local overheating or uneven temperature. This helps ensure product quality and the stability of the production process, allowing users to use the equipment with confidence.

In addition, the heater uses high-quality electrical components and multiple protective measures to ensure safe and reliable operation of the equipment. At the same time, the product has multiple safety protection functions such as overheating, overvoltage, and leakage, which effectively prevents accidents and provides users with comprehensive safety protection.

Product Parameter

| Specifications | Power | Pipeline heater(liquid) | Pipeline heater(gas) | ||

| KW | Heating room size(mm) | Connection diameter(mm) | Heating room size(mm) | Connection diameter(mm) | |

| XTGD-5 | 5 | DN80*500 | DN25 | DN100*600 | DN25 |

| XTGD-10 | 10 | DN80*700 | DN32 | DN100*700 | DN32 |

| XTGD-15 | 15 | DN125*700 | DN32 | DN125*700 | DN32 |

| XTGD-20 | 20 | DN150*800 | DN40 | DN150*900 | DN40 |

| XTGD-30 | 30 | DN150*800 | DN40 | DN150*1000 | DN40 |

| XTGD-40 | 40 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-50 | 50 | DN200*1000 | DN50 | DN200*1200 | DN50 |

| XTGD-60 | 60 | DN200*1200 | DN50 | DN250*1300 | DN80 |

| XTGD-80 | 80 | DN250*1400 | DN80 | DN250*1500 | DN80 |

| XTGD-100 | 100 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-120 | 120 | DN250*1600 | DN80 | DN300*1600 | DN100 |

| XTGD-150 | 150 | DN300*1600 | DN100 | DN350*1600 | DN125 |

| XTGD-180 | 180 | DN300*1600 | DN100 | DN350*1800 | DN125 |

| XTGD-200 | 200 | DN300*1800 | DN100 | DN400*1800 | DN150 |

| XTGD-240 | 240 | DN350*1800 | DN125 | 2*DN300*1600 | DN150 |

| XTGD-280 | 280 | DN350*1800 | DN125 | 2*DN350*1600 | DN150 |

| XTGD-300 | 300 | DN400*1800 | DN150 | 2*DN350*1600 | DN150 |

| XTGD-360 | 360 | DN400*1800 | DN150 | 2*DN350*1800 | DN150 |

| XTGD-400 | 400 | 2*DN300*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-450 | 450 | 2*DN350*1800 | DN150 | 2*DN400*1800 | DN150 |

| XTGD-500 | 500 | 2*DN350*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-600 | 600 | 2*DN400*1800 | DN150 | 2*DN450*1800 | DN150 |

| XTGD-700 | 700 | 2*DN400*1800 | DN150 | 2*DN500*1800 | DN150 |

| XTGD-800 | 800 | 4*DN300*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-900 | 900 | 4*DN350*1800 | DN150 | 4*DN400*1800 | DN150 |

| XTGD-1000 | 1000 | 4*DN350*1800 | DN150 | 4*DN450*1800 | DN150 |

details

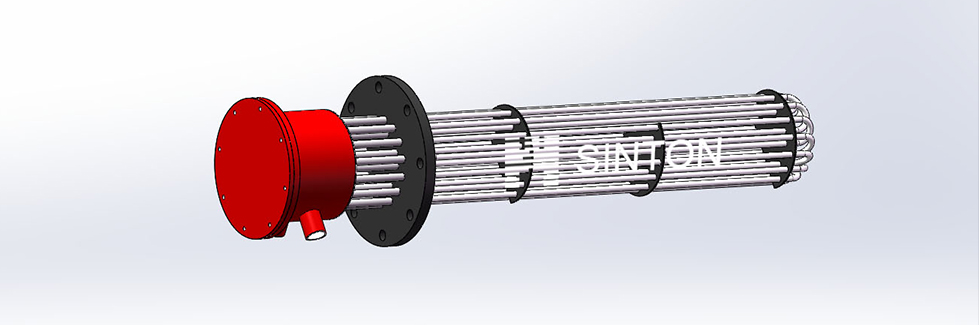

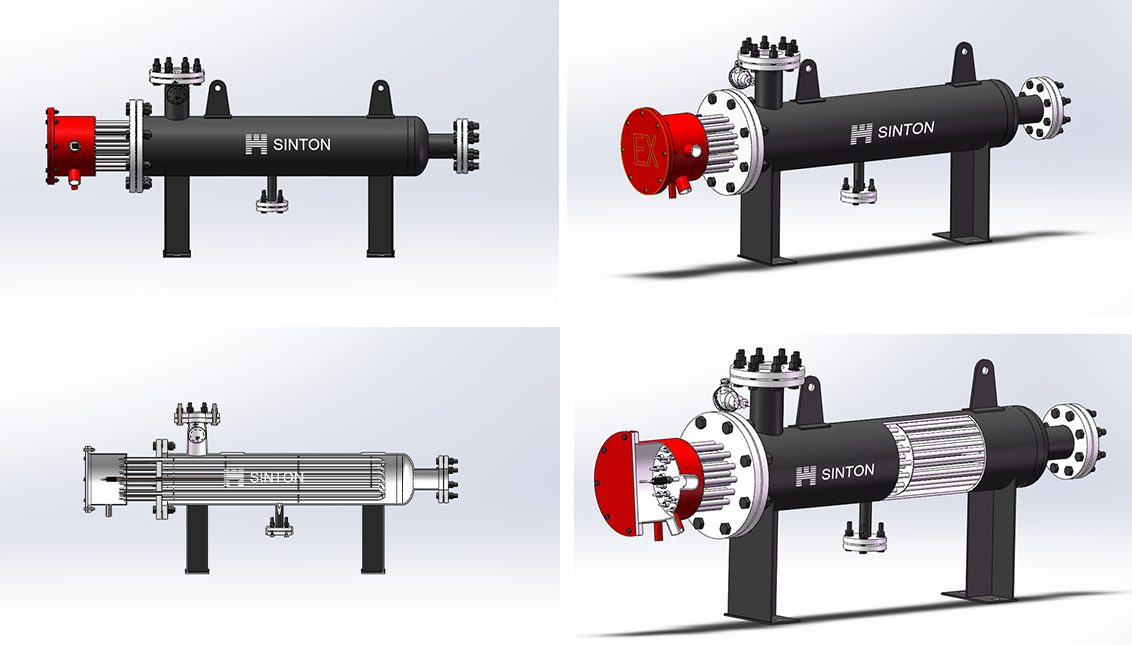

Sinton Pipeline Heaters short heat-up time, replacement, or easy set of features and benefits that include: more economical open coil elements to provide efficient heat transfer.

•Ceramic that has the ability to bear high thermal heat is mechanical support for coils.

• Compatibility of thermocouples for temperature regulation

• Use of steel pipes for their thermal and corrosion resisting property.

Sinton Pipeline Heaters are efficient with inline heaters (circjson heaters) directly immersed in the liquid to transfer electric power into heating the substance or element effectively. This is much more efficient than other sources of heating, losing the potential energy. Inline heaters are easy to install, maintain, and also can be transferred between applications; therefore, inline heaters are versatile in many industries. Pipeline Heaters - Process Skids: For applications at sites

details

The Sinton Pipeline Heaters are so versatile in their applications that they can be used for:

They are designed for oil, gas, food processing, and power production industries to provide efficient solutions in heating through a wide spectrum of applications.

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE