Heating Equipment

Induction heating thermal conductive oil boiler refers to a device that uses the principle of induction heating to heat thermal conductive oil.

Induction heating is a non-contact heating method that uses electromagnetic induction to generate eddy currents in conductors and convert them into heat energy. In a thermal oil boiler, an induction heating coil surrounds the outside of the pipe or container of thermal oil. When current passes through the coil, eddy currents are generated inside the pipe, causing the thermal oil to heat.

This type of boiler is often used in industrial applications that require high-temperature thermal oil, such as chemical industry, plastic processing, rubber, food processing and other fields. As a heat carrier, thermal oil has good thermal conductivity and stability, and can evenly transfer heat to the equipment or process that needs to be heated.

Compared with traditional flame heating or resistance heating, induction heating has higher energy efficiency, faster heating speed and more precise temperature control. It can also reduce energy waste and environmental pollution.

details

Working principle

Working principle

The principle of electromagnetic induction heating is that the alternating current generated by the induction heating power supply generates an alternating magnetic field through the sensor (i.e., the coil), and the magnetic conductive object is placed in it to cut the alternating magnetic field line, thereby generating an alternating current (i.e., eddy current) inside the object. The eddy current causes the atoms inside the object to move irregularly at high speed, and the atoms collide and rub against each other to produce heat energy, which has the effect of heating items.That is, by converting electrical energy into magnetic energy, the heated steel body induces magnetic energy and generates heat.

Advantages of electromagnetic heating:

1. It can be heated quickly. Electromagnetic waves can generate induced current in the object, causing heat to be directly generated inside the object. The energy is greatly utilized and the heating speed is rapid;

2. The temperature can be adjusted accurately. Electromagnetic heating can accurately control the heating power. Compared with traditional heating methods, temperature adjustment is more flexible;

3. High safety, because electromagnetic heating generates induced current and does not require flame or open flame, so there is no risk of open flame explosion;

4. It can reduce energy consumption. Electromagnetic heating only generates heat for the objects that need to be heated. There is no heat loss in traditional heating methods, so it is more energy-saving.

5.Safe and reliable: oil-electricity separation, no coke accumulation, and no leakage greatly improve the safety of use.Low-voltage soft start reduces the harm of current surges and avoids damage to equipment due to voltage fluctuations.The frequency conversion power output part can automatically adjust the size of the current according to voltage fluctuations to ensure constant power and will not be damaged due to insufficient electrical carrying due to the increase in voltage and current.Heat gathers inside the heating body, and the surface temperature of the electromagnetic coil is slightly higher than the indoor temperature, which can be safely touched and has good insulation without high temperature protection.

6.High-efficiency and energy-saving: high-frequency electromagnetic induction heating, through electromagnetic induction directly acts on the water tank, causing the water tank itself to heat up, reducing the process of conduction through the medium, less heat loss, high thermal efficiency, instant heating, no need for heat storage capacity, instantaneous thermal efficiency can be as high as 98% or more, under the same conditions, it is 20% energy-saving than natural gas, which greatly saves production costs.

7.Accurate temperature control: the coil itself does not generate heat, the thermal resistance is small, the thermal inertia is low, the temperature of the inner and outer walls of the barrel is consistent, the temperature control is real-time and accurate, the oil temperature control ability is significantly improved, and the production efficiency is high.

8.Improve the environment: electromagnetic heating equipment adopts internal heating method, the heat is gathered inside the heating body, and the external heat is not dissipated.Adopt clean energy and eliminate emissions of harmful substances such as carbon dioxide.Create an environmentally friendly, safe and comfortable production environment for front-line production personnel.

9.Service life: industrial-grade electromagnetic, high-temperature resistant wire, used for more than 15 years.

10.Quiet sound: The frequency of the thermal power supply is 20,000 HZ, which exceeds the normal listening frequency of the human body, which not only improves the thermal efficiency, but also is silent and environmentally friendly.

11.Maintenance: Electromagnetic induction heating. When working, the core component of heating is a fixed magnetic field. After the water passes through, it is magnetized and the structure of the water is magnetized. The system is maintenance-free.

Explosion-proof electromagnetic heater performance

1.The main structure is made of steel with strong load-bearing capacity;

2.Heat is transmitted inward, with high thermal efficiency;

3.Inlet and outlet oil temperature meter display, easy to monitor;

4.The heating power is freely switched to maintain a constant temperature;

5.The ambient temperature is within 100℃, freely adjustable;

6.Summary display of traffic data, intelligent management;

7.The pressure display function is complete, which is easy to monitor;

8.The control box is sealed and safe, fireproof and explosion-proof;

9.Automatic alarm for temperature detection, good safety.

Product Parameter

Technical parameters

| Model number | XTDC-30 type |

| Heating barrel body | diameter DN65 carbon steel magnetic conductive barrel body, pressure 2.5 MPa pressure test to ensure safety |

| Heating power | single barrel power 15KWx2 groups |

| Voltage | Main circuit 380V, control circuit 220V |

| Working frequency | 50HZ |

| Thermal efficiency | >98% |

| Design temperature | 60°C |

| Temperature control accuracy | +1-2°C |

| Temperature sensor | K |

| Equipment accessories | the piping, elbows, and adaptations within the range are all made of A3 seamless steel pipe |

| Applicable conditions of equipment | A.Altitude ≤3000m B.Ambient temperature-30—40C° C.Relative humidity≤90% D.No severe vibration, no corrosive gas environment |

| Dimensions and weight | A.Width 750mmx length 1500mm height 1500mm B.350kg |

details

Disadvantages of electromagnetic heating:

1. The cost is higher. Compared with traditional heating methods, electromagnetic heating equipment is more expensive;

2. There are limitations to the materials that can be heated. Electromagnetic heating is only for conductive materials, and insulating materials cannot be heated directly;

3. Compared with resistance heating, the structure is more complex and requires more professional knowledge.

Advantages of resistance heating:

1. Simple structure, low cost and high popularity.

2. Widely used. Resistance heating is widely used in industrial production, home hygiene and scientific research;

3. Easy to control. Precise heating control can be achieved by adjusting the current and voltage, which is easy to operate;

4. High heating temperature. Resistive heating can produce very high temperatures and can be used in a variety of environments;

5. The heating effect is stable. Resistance heating can maintain the temperature stably during the heating process and is more in line with traditional heating methods.

Disadvantages of resistance heating:

1. High energy consumption. Resistive heating typically produces more heat loss and is therefore more energy-intensive;

2. Heating speed is slow. Resistive heating takes a relatively long time to reach the desired temperature;

3. Safety hazards. Because resistance heating requires electric heating, circuit leakage or electrical failure may cause safety risks;

4. Facing material limitations. Some materials, such as ceramics, glass, etc., are difficult to conduct resistance heating due to their non-conductive properties.

The elements for selecting electromagnetic heaters include:

1. Energy efficiency and heating speed: In applications that pursue high energy efficiency and rapid heating, electromagnetic heaters may have more advantages.

2. Temperature control requirements: In occasions that require more precise temperature control, the temperature adjustment flexibility of electromagnetic heating may be more suitable.

3. Safety considerations: The characteristic of no open flame and explosion hazard is an important factor in some environments with higher safety requirements.

4. Application fields and material restrictions: Judging whether electromagnetic heating is applicable according to the material of the object being heated, such as whether it is conductive.

5. Cost factors: Although the price of the electromagnetic heater is higher, when considering the energy efficiency and long-term costs comprehensively, it may still be attractive.

6. Heating effect stability: For applications with higher requirements for temperature stability during the heating process, it is necessary to weigh the performance of different heaters.

7. Specific industry needs: For example, in some industrial fields, there are specific requirements for high-temperature heat transfer oil, and it may tend to choose electromagnetic heaters.

Oilfield application case analysis

Natural gas combustion and heating are generally used for crude oil in China's oil fields. During the heating process of this method, the equipment is large in size, and harmful substances such as nitrogen dioxide are produced during the combustion process. There is secondary pollution, natural gas is flammable and explosive, and safety production accidents are prone to occur.The heating process is complex, and the secondary conduction of heat needs to be carried out through the aqueous medium, and the heat loss is large.The vast area of the oilfield has tight water sources, and the water in the cold areas of the north is easy to freeze, which restricts the use of natural gas as a heating method.Natural gas heating requires manual maintenance, which increases labor costs.The equipment of electromagnetic heating method is small in size, no harmful substances such as nitrogen dioxide will be produced during the heating process, there is no secondary pollution, no dangerous goods such as flammable and explosive, and the safety performance is reliable.It is not easy to have safety production accidents.The heating process is direct, and there is no need for secondary heat conduction through the medium of water. The mode of direct heating of crude oil by electromagnetic equipment is used, and there is no heat transfer loss.The electromagnetic heating mode does not require manual maintenance, which saves labor costs.Therefore, the electromagnetic heating mode is more suitable for heating crude oil in Chinese oil fields.

For heavy oil and high-condensate oil extracted from Liaohe Oilfield, the oil recovery capacity of each machine is 30t/day, the oil outlet wellhead temperature is 10℃, and the oil outlet temperature is about 40℃ after heating. The temperature difference is calculated according to 30℃, and the design pressure is 2.5MPa.The minimum temperature in winter is -35℃, and the average temperature throughout the year is 8-9℃.In view of the actual situation of Liaohe Oilfield, we recommend the promotion of the use of electromagnetic heating mode.

Environmental adaptability

1.Temperature: -20℃~60℃;

2.Humidity: ≤95%

3.The operating frequency is between 14-28kHz, and between 15-22kHz is recommended.

Basic performance overview

1.Voltage and power characteristics: 300V-450 constant power output;

2.Thermal efficiency≥90%;

3.IGBT overheating protection temperature: 95±5℃, IGBT overcurrent protection function, phase loss protection function;

4.Working frequency: 14-28kHz;

5.Using a full-bridge series resonant circuit topology, driven by a high-performance IGBT driver chip, and a high-efficiency resonant operating mode;

6.It has a soft-start heating/stopping mode, which is safe and reliable and has a long service life under frequent start-up.;

7.With heating coil short circuit protection function;

8.It has a temperature detection port with an accuracy of 10 digits, and the detection temperature range is 0-150℃; it can be set to a soft switch to control the start and stop.;

9.With multiple coils superimposed with a power of more than 999KW, it works without interfering with each other.;

10.Can be connected to the machine to work; multiple movements work together without interfering with each other;

11.Using unique technology, the circuit is precisely controlled to work efficiently in the weak inductance zone, and the movement can work at more than 500 degrees to maintain a constant power output.;

12.The average trouble-free time is more than 10,000 hours;

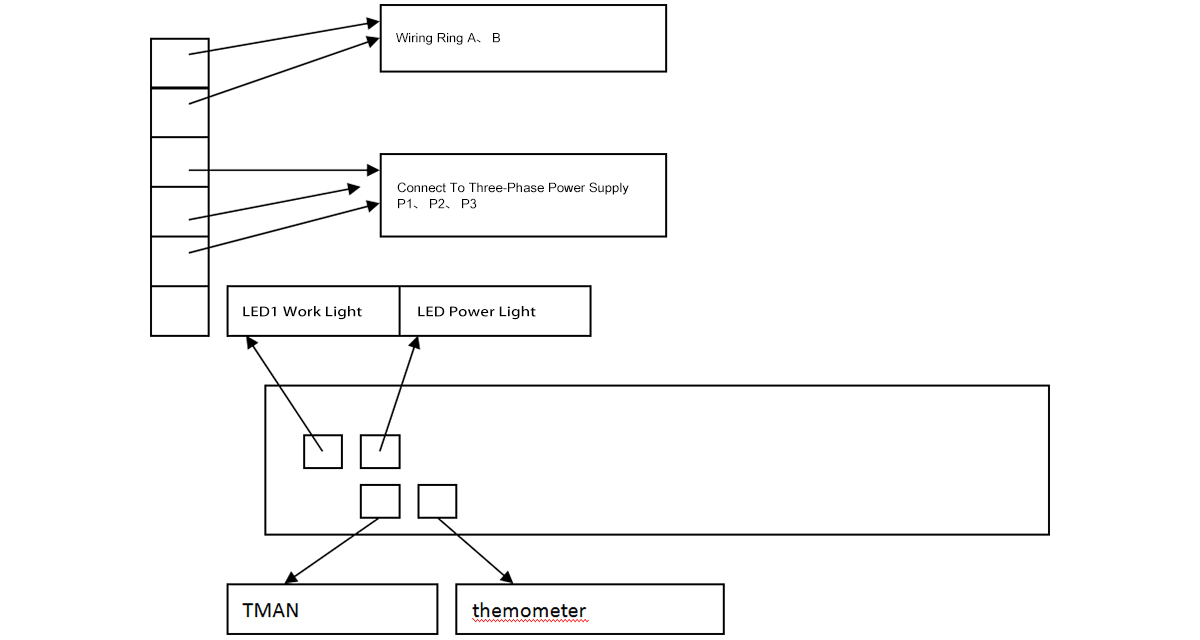

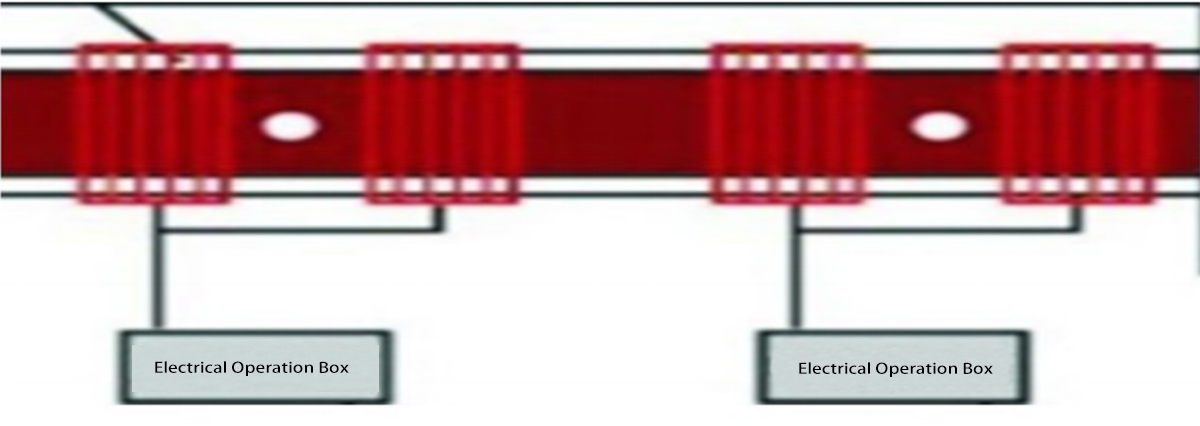

System wiring description and schematic diagram

details

Application

1. The coal-to-electricity industry has been widely used, such as cotton drying, jujube drying, corn drying, grain drying, etc.

2. Plastic and rubber industries, such as film blowing machines, wire drawing machines, injection molding machines, granulators, rubber extruder, vulcanizing machine, cable production extruder, etc. for plastics.

3. The pharmaceutical and chemical industry, such as: special infusion bags for medicine, plastic equipment production lines, liquid heating pipelines in the chemical industry, etc.

4. Energy and food industries, such as the heating of crude oil pipelines; food machinery, such as super cargo planes and other equipment that requires electric heating.

5. High-power commercial induction cooker movement.

6. Building materials industry, such as: gas pipe production line, plastic pipe production line, PE plastic hard flat mesh, geotechnical mesh unit, automatic hollow forming machine, PE honeycomb panel production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC hard pipe, core layer foamed pipe production line, PP extruded transparent sheet production line, extruded polystyrene foamed pipe, PE stretch film unit.

7. Drying and heating in printing equipment.

Electromagnetic heater care

Regarding the service life of electromagnetic heaters, everyone's attention has gradually been paid to them.The service life of electromagnetic heating controllers generally ranges from three to five years, but its service life is greatly related to several factors.

1.Whether the product is installed correctly.The thickness of the thermal insulation cotton required for each electromagnetic heater and electromagnetic heating ring, the thickness and length of the winding, the inductance value, and the input current value are all different, and must be in accordance with the manufacturer's installation instructions at the factory as the standard.And the spacing between the coil groups between each electromagnetic heating control board is more than 10cm is also very important, because getting too close will affect each other.Only when the electromagnetic heater is installed within the normal parameter range can the long-term stable operation be guaranteed.

2.The environment of the workshop includes dust, dust, and humidity.Generally speaking, the greater the dust, the more unfavorable it is for the electromagnetic heating control motherboard.If the dust is relatively large, the fan on the electromagnetic heater needs to be cleaned regularly. The air-cooled electromagnetic heater mainly dissipates heat, and the indoor ventilation is better to avoid the fan being stuck and the motherboard cannot dissipate heat, causing the components to overheat and burn out.

3.The degree of love for the product.For users with relatively large dust and dust in the workshop, they should regularly brush the fan on the electromagnetic heater with a brush, and the dust on the electromagnetic heating coil. For the coil, there is no need for heavy objects to hold it down or cut it. Do not often splash water on the coil or the electromagnetic induction heater.Not to mention exposing the electromagnetic heater to an open-air environment, because if the open-air environment encounters a rainy day, it will definitely get wet, and it will cause damage if it is turned on without drying out.Or in the open-air environment, there is more rain and dew in the morning, which causes the circuit board to be wet. Turning on without drying will also cause the circuit inside to be shorted.

Installation instructions

1.The high-current input and output connection lines should be tightly fixed to ensure good contact and prevent the joints from heating up.

2.The chassis must be well grounded to prevent static electricity and lightning strikes;

3.To connect to the external control interface, pay attention to the polarity, and the connection line should not be wound with the high-current line to avoid interference.;

Basic working parameters

Working voltage range: 320VAC–420VAC

Frequency range: 4kHz ~40kHz (normal full-power operating frequency is 13 kHz to 22kHz)

Coil inductance determination:

The inductance of the coil can be wound with reference to the parameters provided in the table below. The inductance difference is too far or the diameter is not appropriate, which will make the heater work abnormally.Depending on the purpose, the parameters will be slightly different.In addition, when multiple machines work together, the coils of different machines are separated by more than 20CM to avoid mutual interference.

Winding of coils

The winding method of the coil is slightly different according to each usage situation and the difference in power. In most cases, the winding method is shown in the figure below: Before winding, wrap about 25mm thick thermal insulation cotton, and leave 10 to 20CM intervals for each section. Then wrap the next section. The temperature measuring probe of the thermostat can be fixed in the interval area.

Company Qualification Certificate

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE