Heating Equipment

The hot air circulation drying oven is a high-performance equipment designed for the purpose of efficient drying. It utilizes a advanced air circulation technology to ensure uniform and thorough drying of various materials.

details

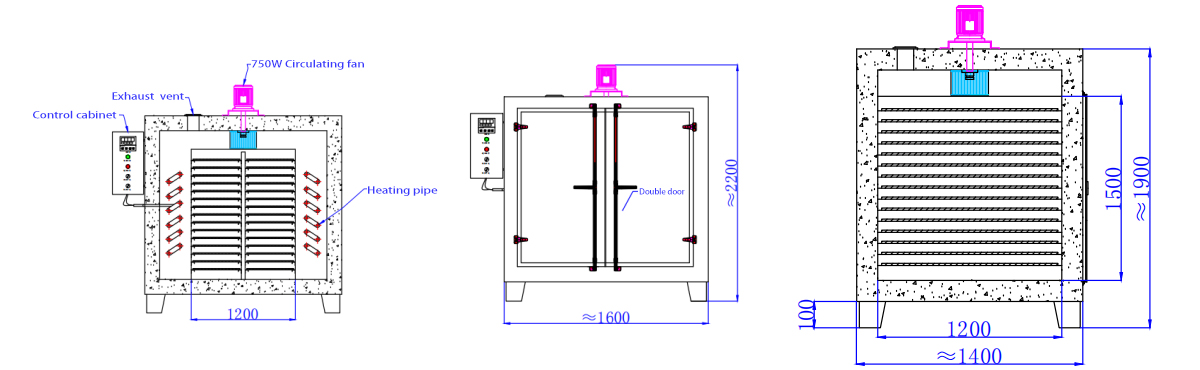

Hot Air Circulation Drying Oven Structure

The oven consists of a box body, an electric heating pipe, an electrothermal blast system and a temperature control system. The box body is composed of an inner cavity and an outer shell, the surface of the case body is sprayed with paint, the color is suitable and the appearance is generous. The studio is made of stainless steel or carbon steel according to customers' requirements. Room can be placed according to customer requirements, the inside and outside box shell filled with aluminum silicate cotton insulation layer, the studio and the door between the sealing strip, to ensure the sealing of the studio.Separate installation of control cabinet on the side of oven for easy operation and maintenance.

The electrothermal blast system consists of a fan, an air duct and a heating element.

The temperature control system is composed of a temperature control instrument, a temperature sensor, an electric heating tube, etc.

Hot Air Circulation Drying Oven Drawing

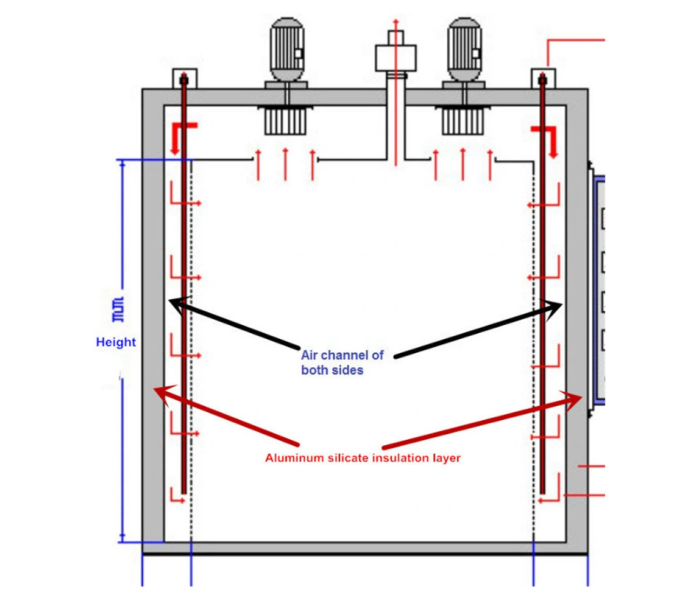

Drying Machine Working Principle

The hot air circulation drying oven is the use of electricity as a heat source, is heated by a heater, a lot of hot air is circulated in the oven, through continous supply of fresh air from air inlet into the oven. and then discharge from we exhaust outlet, thus increasing the heat transfer effect, so that the inside material moisture gradually reduced.

The oven uses a digital display temperature regulator and a temperature measuring element to form a measuring, adjusting and controlling circuit. The temperature measuring element is used as a sensor to measure the temperature of the workroom in the electric heating process, and the output signal is amplified by the digital control circuit in the temperature control instrument. Then it is sent to the LED display circuit to display the measured temperature, and the other one is sent to the comparator to compare with the set value. When the positive deviation between them is generated, the digital control circuit sends out the trigger signal, the contactor absorbs, and the output electric power makes the heating tube heated. When the deviation is reduced to 00:00, the contactor is disconnected, the output power is stopped, the heating tube stops heating, the output of heating in digital control circuit is adjusted by PID, and the system has the function of linear correction of temperature measurement and so on.

When the machine is turned on, the fan switches first, and then the heating switch. When the fan is running, the cold air flow in the working room will flow in from all around through the impeller and the air duct, and the hot air flow will flow out from the middle, so that the indoor temperature will be uniform.

Schematic diagram of hot air circulation

The main features of the hot air circulation drying oven include:

1. Precise temperature control: It allows for accurate setting and maintenance of the desired temperature, ensuring optimal drying conditions.

2. Even heat distribution: The circulating air ensures that the heat is distributed evenly throughout the chamber, resulting in consistent drying outcomes.

3. Large capacity: Sufficient space to accommodate a considerable amount of materials for efficient processing.

4. Adjustable parameters: Users can customize various settings such as temperature, time, and air flow to meet specific drying requirements.

5. Sturdy construction: Built with durability in mind to withstand long-term use and provide reliable performance.

6. Energy-efficient: Designed to minimize energy consumption while maximizing drying efficiency.

7. Easy to use: Intuitive controls and user-friendly interface make operation straightforward.

8. Versatile applications: Suitable for a wide range of materials, including samples, products, and components.

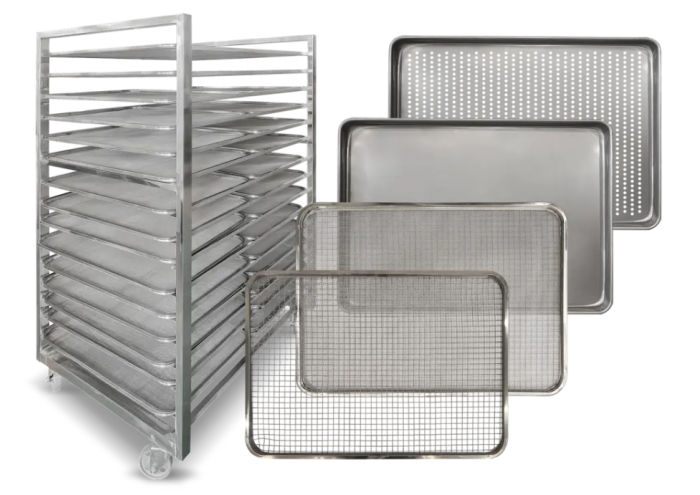

Tray Types

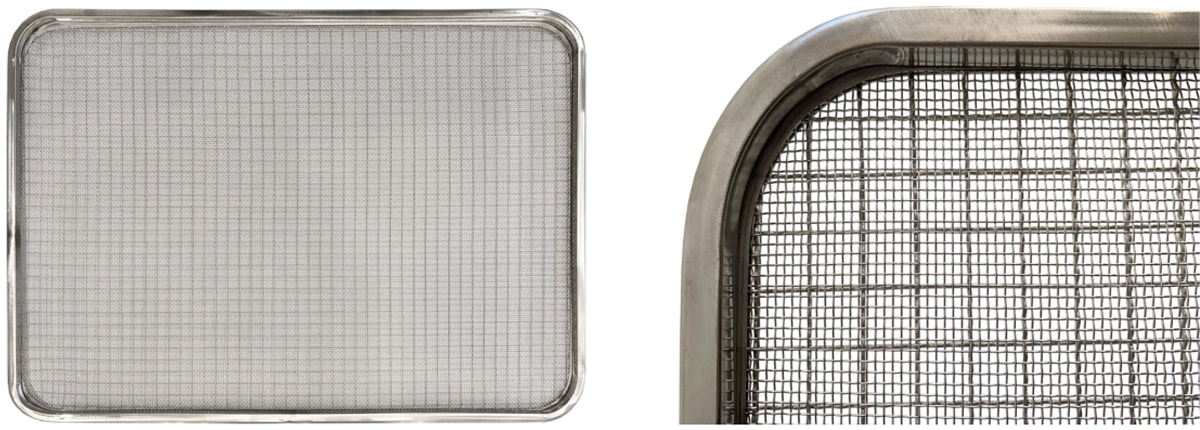

Industrial Mesh Tray

Industrial Fine Mesh Tray

Industrial Perforated Pan Tray

Industrial Flat Pan Tray

Uniform Drying Without Rotation

With our advanced dynamic airflow panels, you will experience evenly distributed hot, dry air across every tray, eliminating the need to rotate your product or trolleys during the drying cycle. Meticulously laser-cut for optimal precision, these panels generate back pressure within the heating chamber, ensuring uniform drying throughout the chamber. With this technology, you can achieve consistent and efficient drying results without extra effort or intervention.

ISO 9001 Manufacturing Facility

Designed and manufactured in an ISO9001-certified facility, it ensures the highest quality standards are met throughout the entire manufacturing process. This internationally recognized standard for quality management systems is a testament to our commitment to excellence in every aspect of our operations, from design to production and beyond. Our ISO9001 certification assures our customers that we adhere to strict quality control processes, using only the highest quality materials and manufacturing techniques to ensure our products’ reliability, performance, and safety. By choosing our ISO9001-certified dehydrators, you can be confident in the quality and consistency of your drying results, and trust that you are investing in a product that has undergone rigorous testing and meets the highest standards of quality and safety.

Completion Cooling Cycle

Our Industrial Dehydrators feature a Completion Cooling Cycle, a vital part of any production process. This cycle ensures that your product is fully cooled to a safe temperature before being handled or packaged. This is important for worker safety, as stainless steel trolleys and trays can hold heat for quite some time. Additionally, bringing the core temperature of your product down fully prior to packaging prevents condensation or moisture from building up inside your packaging during storage, which can affect your product’s quality and shelf life. With our Completion Cooling Cycle, you can ensure the safety and quality of your end product while minimizing waste and maximizing efficiency.

Energy-Saving Technology

Our Industrial Dehydrators incorporates a patented Power-Throttling Technology that adjusts the power output based on the set temperature of the chamber. This innovative design allows the units to operate at a reduced power rating, resulting in an impressive 35-45% increase in energy efficiency compared to traditional drying ovens. With our energy-saving technology, you can achieve the same great results while reducing your energy consumption and costs.

Premium High-Quality Components

Our industrial dehydrators are built using only the highest quality components and parts, ensuring unparalleled performance and durability. We pride ourselves on using top-grade brands such as Siemens and Schneider for our components, ensuring that our dehydrators are reliable and built to last. Our commitment to using the best components and parts is just one of the ways we ensure that our customers receive the best products possible.

Food-Grade 304 Stainless Steel

Our Industrial Dehydrators are constructed with the highest quality 304 Food-Grade Stainless Steel available. This stainless steel grade contains higher levels of chromium and nickel, which forms a protective layer on the surface, preventing corrosion (rust), and preventing the formation of bacteria and other microorganisms. Additionally, it’s non-reactive and won’t react with acidic or alkaline substances found in food and cleaning agents. This steel is also very easy to clean and sanitize, which is essential in food production facilities. In summary, using food-grade stainless steel ensures food safety and hygiene by preventing contamination and maintaining the quality of the food being processed.

Speedy 1-Month Manufacturing & Delivery

We pride ourselves on delivering high-quality custom-built dehydrators to meet your specific needs and your onsite electrical requirements. From production to delivery, our team works closely with you to ensure your machine perfectly suits your unique requirements. And thanks to our streamlined manufacturing process, we can deliver your custom-built dehydrator to your doorstep in just one months. That means you won’t have to wait long to start enjoying the benefits of your new machine.

Remarkable Feature of Hot Air Circulation Drying Oven

Most of the hot air is circulated in the oven, high thermal efficiency, and energy saving.

Positive draft function with an adjustable plate to separate air enables the materials to be dried evenly.

Low noise, balanced running, automatic temperature control, convenient installation and maintenance.

Wide application range, a variety of materials can be drying, one kind of general drying equipment.

Made of high-quality materials: carbon steel, aluminum alloy, stainless steel.

Product Parameter

Main technical parameters of equipment:

|

Model B) |

Power |

Heater inner dimension (length * width * height) |

Voltage |

Motor power |

Working temperature |

Thermal efficiency |

|

XTDQ-HX-1 |

1KW |

250mm*250mm*250mm |

220V |

40W |

RT-300℃ |

>90% |

|

XTDQ-HX-1.6 |

1.6KW |

350mm*350mm*350mm |

220V |

40W |

RT-300℃ |

>90% |

|

XTDQ-HX-2.2 |

2.2KW |

350mm*450mm*450mm |

220V |

40W |

RT-300℃ |

>90% |

|

XTDQ-HX-3.2 |

3.2KW |

450mm*550mm*550mm |

220V |

40W |

RT-300℃ |

>90% |

|

XTDQ-HX-4.6 |

4.6KW |

500mm*600mm*750mm |

220V |

180W |

RT-300℃ |

>90% |

|

XTDQ-HX-9 |

9KW |

800mm*800mm*1000mm |

220V/380V |

180W |

RT-300℃ |

>90% |

|

XTDQ-HX-12 |

12KW |

800mm*1200mm*1200mm |

220V/380V |

370W |

RT-300℃ |

>90% |

|

XTDQ-HX-15 |

15KW |

1000mm*1200mm*1200mm |

380V |

370W |

RT-300℃ |

>90% |

|

XTDQ-HX-18 |

18KW |

1000mm*1200mm*1500mm |

380V |

750W |

RT-300℃ |

>90% |

|

XTDQ-HX-21 |

21KW |

1200mm*1200mm*1500mm |

380V |

750W |

RT-300℃ |

>90% |

|

Size > 21KW model and non-standard products can be customized according to customer requirements. |

>90% |

|||||

Note:1. With "B" for stainless steel inner tank, no "B" for carbon steel;

2. The above data are measured with K type thermocouple at ambient temperature of 20℃ and relative humidity below 85%.

3. RT is ambient temperature.

details

Drying oven description

The drying oven is a high-performance equipment designed for the purpose of efficient drying. It utilizes a advanced air circulation technology to ensure uniform and thorough drying of various materials.

The main features of the drying oven include:

1. Precise temperature control: It allows for accurate setting and maintenance of the desired temperature, ensuring optimal drying conditions.

2. Even heat distribution: The circulating air ensures that the heat is distributed evenly throughout the chamber, resulting in consistent drying outcomes.

3. Large capacity: Sufficient space to accommodate a considerable amount of materials for efficient processing.

4. Adjustable parameters: Users can customize various settings such as temperature, time, and air flow to meet specific drying requirements.

5. Sturdy construction: Built with durability in mind to withstand long-term use and provide reliable performance.

6. Energy-efficient: Designed to minimize energy consumption while maximizing drying efficiency.

7. Easy to use: Intuitive controls and user-friendly interface make operation straightforward.

8. Versatile applications: Suitable for a wide range of materials, including samples, products, and components.

Performance of the hot air circulating oven:

1. High temperature control accuracy: It can precisely set and maintain the required temperature range.

2. Good temperature uniformity: Ensure that the temperature in all parts of the oven is consistent, avoiding the situation of local overheating or overcooling.

3. High drying efficiency: Accelerate the evaporation of moisture through the hot air circulation, and shorten the drying time.

4. Good ventilation performance: It is beneficial to the uniform distribution of hot air and the exhaust of moisture.

5. Strong adjustability: Parameters such as temperature, wind speed, and time can be adjusted according to different materials.

6. Good stability: It can maintain stable performance in long-term operation.

7. Energy saving and environmental protection: It has a higher thermal efficiency and can reduce energy consumption and the impact on the environment.

8. Safe and reliable: It is equipped with safety devices such as overload protection and overheating protection.

9. Easy to operate: The interface is friendly, easy to operate and monitor.

10. Convenient for maintenance: The structural design is reasonable, and it is convenient for daily maintenance and maintenance.

11. Wide application range: It can be used for the drying, baking and other treatments of a variety of materials.

12. Durable material: It has a long service life and can withstand a certain work intensity and environmental conditions.

Application:

Our industrial drying oven is widely used in electronics, toys, paint processing, ornaments, motors, communications,electroplating, plastics, hardware and chemical industry, printing, spraying, glass, ceramics, high temperature stress relief,aging, drying, finalization and processing.

It can also be used to drying articles with chemical gas, substrate stress removal, ink curing, paint film drying, etc.

How to select the hot air circulating oven?

When selecting the hot air circulating oven, the following are some elements that need to be considered:

1. Capacity demand: Determine the required oven capacity according to the quantity and size of the materials.

2. Temperature range: Ensure that the oven can meet the temperature requirements of a specific drying or heating process.

3. Temperature control accuracy: High-precision temperature control is crucial for some applications.

4. Uniformity: The temperature inside the oven should be evenly distributed to ensure that the materials are heated uniformly.

5. Effect of hot air circulation: Good circulation can improve the drying efficiency.

6. Material and quality: Select durable and reliable materials.

7. Safety: Have safety functions such as overload protection and overheating protection.

8. Operational convenience: The interface is simple and easy to set up and monitor.

9. Energy-saving performance: Reduce operating costs.

10. Brand and reputation: Well-known brands usually have better quality and after-sales service.

11. Price: Consider the budget on the premise of meeting the requirements.

12. After-sales service: Including support in aspects such as installation, training, and maintenance.

13. Customization options: If there are special requirements, such as specific dimensions or functions.

14. Expandability: Whether it is convenient to carry out equipment upgrades or expansions in the follow-up.

15. Noise level: Especially in an environment where noise is required.

When making a selection, consider these elements comprehensively, and select the most suitable hot air circulating oven according to the specific application requirements and budget.

Specification:

|

Dry Oven Model |

Voltage(V) |

Power(KW) |

Working Temperature |

Inside Dimensions (D*W*H mm) |

|

XTHX-101-1A |

220 |

1 |

indoor-300 deg C |

250*250*250 |

|

XTHX-101-2A |

220 |

1.6 |

indoor-300 deg C |

350*350*350 |

|

XTHX-101-3A |

220 |

2.2 |

indoor-300 deg C |

350*450*450 |

|

XTHX-101-4A |

220 |

3.2 |

indoor-300 deg C |

450*550*550 |

|

XTHX-101-5A |

220 |

4.6 |

indoor-300 deg C |

500*600*750 |

|

XTHX-101-6A |

220/380 |

9 |

indoor-300 deg C |

800*800*1000 |

|

XTHX-101-7A |

220/380 |

12 |

indoor-300 deg C |

800*1200*1200 |

|

XTHX-101-8A |

380 |

15 |

indoor-300 deg C |

1000*1200*1200 |

|

XTHX-101-9A |

380 |

18 |

indoor-300 deg C |

1000*1200*1500 |

|

XTHX-101-10A |

380 |

21 |

indoor-300 deg C |

1200*1200*1500 |

details

Applicable Materials

Drying Effect in Different Application

The same as natural drying. Keep the aroma, shape, colour, taste, nutrition etc.

How To Dehydrated Fruits

PRE-TREATMENT

Pre-treating fruit for dehydration will not only help to maintain the nutritional value and flavor of the fruit, but it will also help prevent browning or oxidation which can occur quite easily with particular fruits at higher temperatures. Bananas, apples, and peaches are prone to oxidation but with a simple pre-treatment, you can keep them looking and tasting great. Two easy ways to pre-treat fruit are either with lemon juice or ascorbic acid (vitamin C).

LEMON JUICE PRE-TREATMENT

This is the most popular way to pre-treat fruit for dehydration but be mindful that using a fruit with a high amount of citric acid can change the flavor slightly of the fruit you’re dehydrating, especially if you’re using lemon juice that’s undiluted. This can actually be pleasant to taste, especially with apples, but if you prefer to keep the lemon flavor to a minimum, follow our suggestions below:- Combine 1 cup of lemon juice with 4 cups of water in a bowl or mix and use in a spray bottle. - Soak each piece of cut fruit in the bowl or spray directly to ensure the fruit is coated.- Make sure you remove excess liquid from the fruit before dehydrating, either with a salad spinner or preferably patting dry with a clean towel or paper towel to absorb any moisture.

ASCORBIC ACID PRE-TREATMENT

Using the same method as above, ascorbic acid can be used in the pre-treatment of fruits for dehydration. See our steps below:

- Mix 2 teaspoons of ascorbic acid with 4 cups of water in a bowl.

- Soak each piece of cut fruit in the ascorbic acid solution for up to 5 minutes and pat dry with a towel or paper towel to remove any excess moisture before dehydrating.

Drying Times

The length of time it takes to dehydrate fruit is really dependent on the water content and how thick the fruit is cut. As mentioned above, thinly sliced fruit will dry faster and more evenly than fruit that’s quartered, halved, or left whole so this is something to consider when preparing fruit for dehydration. Most fruits can take anywhere from 8 hours up to 24+ hours, with berries sometimes needing around 24-48 hours to remove all of their moisture.

Another thing to consider when it comes to drying times is the desired result and texture you’re trying to achieve. For example, if you want your apple slices to be crispy like a chip, that will take slightly longer than if you prefer your apples to have a more chewy texture. Use our guide below as just that—a rough guide for drying times based on fruits being sliced rather than dehydrating them whole. We recommend monitoring the progress of your fruits to ensure you get the texture you’re after.

Shipment

provides customers with quality and safe transportation.

1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MOREUnderstanding Hot Spots in Cartridge HeatersHigh-watt-density cartridge heaters are engineered to deliver significant heat output over a relatively small cross-...

READ MOREHigh-Purity Magnesium Oxide (MgO) InsulationThe primary electrical insulation within tubular heater is composed of high-purity magnesium oxide (MgO), which serv...

READ MOREAs industrial processes continue to demand higher efficiency, safety, and thermal stability, shell and tube heat exchangers remain one of the most reliable and ...

READ MOREConsistent Temperature Control Oil Circulation Heaters are renowned for their ability to provide stable and consistent temperature control. In industrial settin...

READ MORE