WhatsApp: +86-185-5601-8866

Heating Equipment

News

2025-06-17

1. Understanding the Fundamentals of Pipeline Freezing in Cold Climates

Pipeline freezing in cold climates is a multifaceted phenomenon that requires a deep understanding of thermodynamics, material behavior, and fluid dynamics. When ambient temperatures fall below the freezing point of the transported fluid, the heat exchange between the fluid inside the pipeline and the external environment can cause the temperature of the fluid to decrease progressively. If no preventative heating system is in place, this can eventually lead to the fluid reaching its freezing point, resulting in ice formation, increased viscosity, flow restriction, or complete pipeline blockage. In the case of water and aqueous-based solutions, freezing causes volumetric expansion, which can exert internal pressure on the pipe walls, potentially leading to pipe bursts, cracks, or joint failure. This is particularly dangerous in metal pipes with welded or flanged joints, as the mechanical stress generated during freeze-thaw cycles can gradually weaken the structural integrity of the pipeline. It is also crucial to recognize that different fluids have different freezing points; for example, crude oil may not freeze in the conventional sense but can become so viscous in low temperatures that it behaves like a semi-solid, leading to pump strain, compressor overload, and reduced throughput. The surrounding environment plays a pivotal role. In arctic regions or elevated terrains, surface-exposed pipelines are more prone to freezing due to wind chill, snow accumulation, and direct exposure to sub-zero temperatures. Subterranean pipelines, although partially insulated by the earth, are also vulnerable in areas where the ground itself freezes to significant depths. Soil thermal conductivity, groundwater saturation, and permafrost presence can all influence how much cold the pipeline absorbs. Moreover, certain construction materials, such as bare steel or uncoated iron, have higher thermal conductivity and thus transmit cold more efficiently from the environment to the fluid inside. Understanding these variables is the first step toward designing effective anti-freezing strategies.

Another crucial aspect is the flow condition inside the pipeline. A static or low-flow pipeline is more susceptible to freezing than one with continuous, high-velocity flow because movement generates friction and thermal energy. When fluid stands idle in the pipe, especially overnight or during shutdowns, it has ample time to lose heat and reach freezing temperatures. In process plants or refineries operating intermittently, this factor becomes especially significant. Operational factors such as pipeline diameter, wall thickness, and length also affect freezing likelihood. Smaller diameter pipelines freeze faster due to a higher surface-area-to-volume ratio, which increases the rate of heat loss to the environment. The thermal inertia of the system—essentially how long the fluid can maintain its temperature without heating support—is also affected by these physical characteristics. For pipelines transporting hazardous chemicals or hydrocarbons, freezing can not only disrupt operations but also pose serious environmental and safety risks. A cracked pipeline leaking methanol, glycol, or petrochemicals in a remote cold region can lead to ecological contamination, fire hazards, and regulatory violations. Therefore, preventive heating is not just a matter of flow optimization but also of environmental responsibility and safety compliance.

Another element of pipeline freezing is the presence of water vapor, condensation, or moisture within the pipeline. Even in systems transporting gases or dry fluids, residual humidity or condensation due to temperature differentials can lead to localized freezing. This typically occurs at bends, elbows, valves, and fittings—areas where fluid turbulence or temperature anomalies are common. These zones act as “cold traps” and are usually the first locations where ice begins to form. The pipeline's insulation status also greatly affects freezing susceptibility. Bare or poorly insulated pipelines are far more vulnerable to ambient conditions, and insulation alone without supplemental heating is insufficient in extremely cold climates. Over time, thermal degradation of insulation materials or water ingress into the insulation layer can reduce its effectiveness, necessitating regular inspection and maintenance. Engineers must also consider freeze-thaw cycles during transitional seasons when daytime temperatures rise above freezing and nighttime temperatures drop below. These fluctuations cause repeated expansion and contraction of both the pipe material and the fluid, accelerating fatigue, increasing corrosion rates, and compromising sealing elements like gaskets or o-rings. In automated or unmanned operations—such as those found in remote oilfields or cross-border pipelines—the absence of immediate human intervention further amplifies the risks associated with freezing. In such cases, robust design strategies incorporating automatic freeze protection are necessary. Understanding all these fundamental principles is essential before selecting or designing any effective pipeline heating solution in cold climate operations

2. Types of Pipeline Heaters: Electric, Steam, and Induction Systems

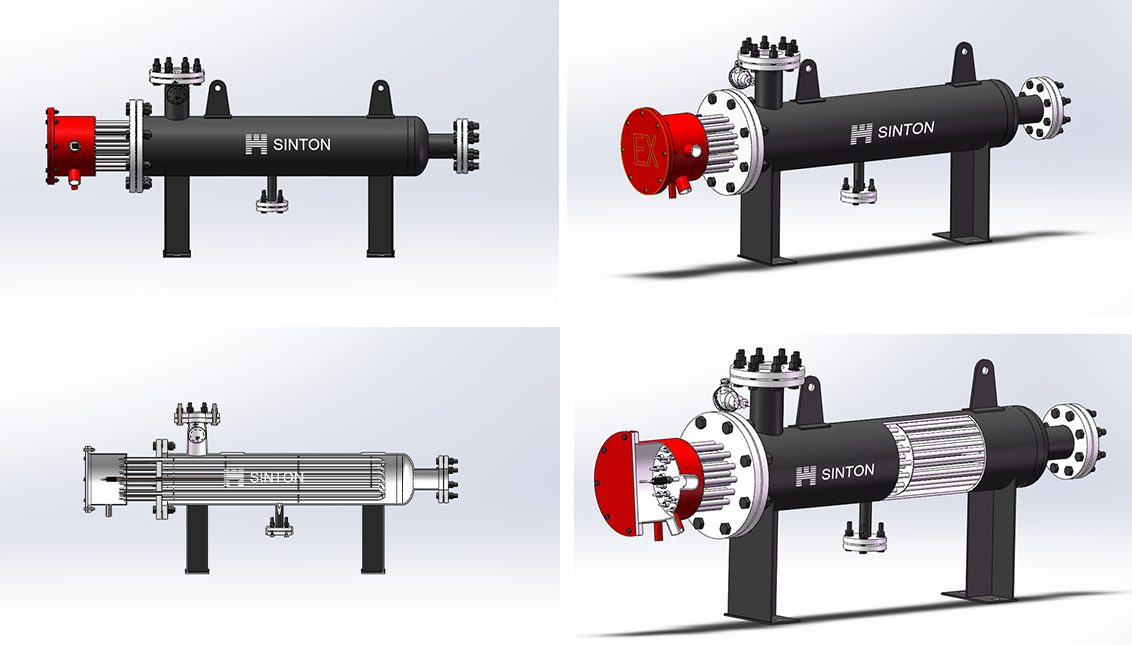

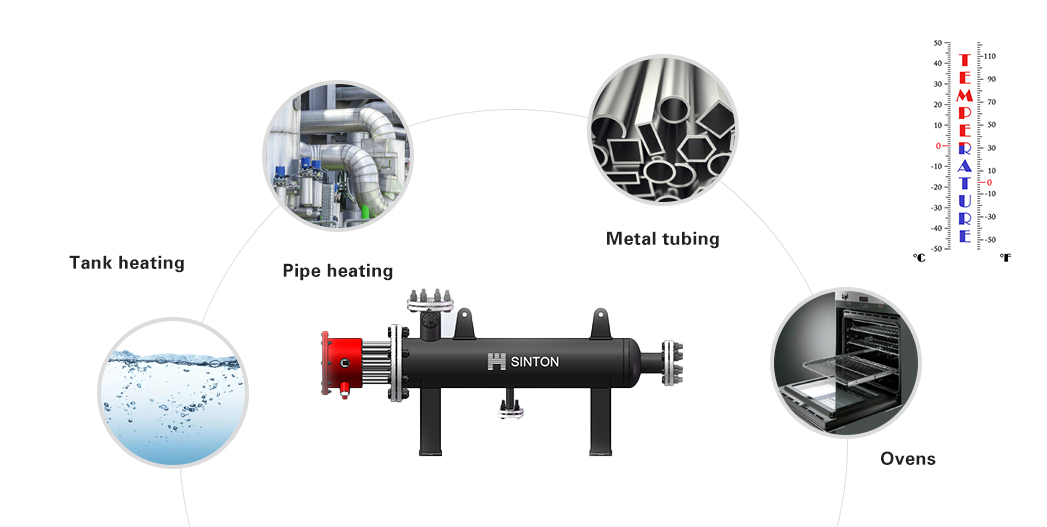

Pipeline heaters are specialized systems designed to maintain the temperature of fluids in pipelines above the freezing point or within the optimal flow range, particularly during extreme cold weather conditions. The selection of the heater type depends on multiple variables such as fluid properties, pipeline length and diameter, power availability, environmental exposure, and operational priorities such as response time, energy efficiency, and safety. The three most commonly employed categories are electric heating systems, steam tracing systems, and induction-based heating solutions, each offering distinct operational benefits and challenges. Electric pipeline heaters are widely used in modern industrial applications due to their precision, ease of control, and ability to be deployed in a modular, decentralized fashion. One of the most popular electric heating methods is electric heat tracing, which involves running an electrically resistive cable along the length of the pipe. When powered, the cable generates heat that is conducted into the pipeline wall, thereby heating the fluid inside. There are two main subtypes of electric heat tracing: constant wattage and self-regulating cables. Constant wattage systems provide a uniform heat output across their length, which is ideal for applications requiring steady-state heating. Self-regulating heat trace cables, on the other hand, automatically adjust their heat output in response to the surrounding temperature, offering energy efficiency and reducing the risk of overheating.

Electric immersion heaters, flange-mounted or screw-plug types, are another category that can be inserted directly into the pipe or into heating jackets surrounding the pipe. These are more appropriate for small-diameter pipelines or short sections requiring high heat density. Electric heating systems also benefit from easy integration with temperature controllers, automated monitoring systems, and IoT devices, making them ideal for facilities requiring high automation. However, electric systems do rely heavily on the availability of stable electricity, and in remote locations, this can be a limitation unless supported by generators or renewable energy sources like solar panels. Steam tracing, in contrast, utilizes high-pressure steam transported through small-diameter tracing tubes that run parallel to or wrap around the pipeline. The steam transfers heat through conduction and radiation to the pipeline, keeping the fluid inside above freezing temperatures. Steam tracing is often used in refineries, petrochemical plants, and older infrastructure where central steam generation is already available. It is highly effective for long runs of pipe and fluids with high thermal inertia. However, it does come with drawbacks, such as the need for complex condensate return systems, higher maintenance requirements, and the potential for steam leaks or corrosion in the tracing lines. Proper insulation is also crucial for steam tracing to maintain efficiency and prevent heat losses. Steam systems are less flexible in terms of zoning and control, making it harder to fine-tune the temperature of different pipeline segments independently.

Induction heating systems represent a more advanced and localized method, using electromagnetic fields to generate heat directly in the metal pipe wall without direct contact. The principle relies on Faraday's Law of electromagnetic induction, where alternating current passing through an induction coil generates eddy currents in the pipeline wall, causing resistive heating. This method is especially valuable in high-viscosity or waxy fluid transport, where rapid heating is needed to maintain pumpability. Induction systems offer rapid thermal response, precise temperature control, and minimal external heat loss due to their non-contact operation. They are particularly suitable for subsea pipelines, offshore platforms, and pipelines with irregular geometries or access constraints. Additionally, since induction heating does not require cables or tubes in physical contact with the pipe, it reduces maintenance needs and avoids common issues such as cable degradation or corrosion. However, induction systems are more capital-intensive and require sophisticated electronic control units, power converters, and coil alignment mechanisms. They also have limitations in terms of heating depth and are generally better suited for smaller pipeline sections or highly localized heating zones. Each of these pipeline heating technologies can be optimized further by pairing with thermal insulation, smart control systems, and energy management platforms. In some cases, hybrid systems that combine electric tracing with steam backup or induction with electric jackets are implemented to balance capital expenditure and operational flexibility. Choosing the right pipeline heating method depends on not just technical specifications, but also environmental regulations, safety considerations, and long-term maintenance strategies.

3. The Role of Insulation in Preventing Freezing and Enhancing Heat Retention

Insulation is a critical element in maintaining the temperature of pipelines in cold climates. It plays a dual role: preventing heat loss to the surrounding environment and minimizing energy consumption by reducing the amount of heat required from heating systems. The effectiveness of insulation depends on a variety of factors, including the type of material, thickness, density, and the application method. Insulating a pipeline helps prevent freezing by maintaining the temperature of the fluid inside above its freezing point, ensuring that it flows smoothly and avoids becoming too viscous or blocked.

One of the key benefits of insulation is its ability to slow down the rate of heat loss to the environment. In cold climates, pipelines are often exposed to freezing temperatures that can rapidly deplete heat from the fluid inside the pipe. Without adequate insulation, the heat generated by pipeline heaters will quickly dissipate, leading to insufficient heating and an increased risk of freezing. Proper insulation helps to trap the heat and keep it within the pipeline system for longer periods, reducing the frequency and intensity of heating required.

The most common materials used for pipeline insulation include mineral wool, fiberglass, polyurethane foam, and polyethylene. Mineral wool, for example, is effective in high-temperature applications and provides a high level of thermal resistance. Fiberglass is often used in commercial and industrial pipeline insulation due to its light weight, cost-effectiveness, and excellent thermal properties. Polyurethane foam is popular in the oil and gas industry because of its superior insulation properties and ability to maintain consistent thermal performance even in extremely cold environments. Polyethylene is frequently used for flexible insulation and pre-insulated piping systems, offering high durability and ease of installation.

The thickness of the insulation is crucial in determining its efficiency. Thicker insulation provides a greater barrier to heat loss, but there is a trade-off between thermal efficiency and installation space. In tight spaces or complex pipeline layouts, the available room for thick insulation may be limited, which can make it difficult to achieve optimal thermal protection. The density of the insulation material also plays a role in determining heat retention. Materials with higher density typically offer better thermal resistance but may be heavier and harder to install.

Another important consideration is the application method of the insulation. Insulation can be applied in several forms: wraps, blankets, jackets, or pre-formed pipe covers. Each method has its advantages depending on the operational conditions and pipeline layout. For example, pre-formed covers are ideal for pipelines with consistent diameters and long straight sections, as they provide a uniform layer of insulation that is easy to install. Jackets and wraps are more flexible and can be applied to pipelines with variable diameters, bends, or joints, where pre-formed insulation might not be feasible. These wraps also provide an added layer of protection against moisture ingress, which can degrade insulation performance over time.

Insulation also provides an added benefit of protecting against condensation on the external surface of the pipeline. In cold weather, moisture in the air can condense on the outer surface of the pipe and freeze, adding to the potential for ice formation. This is especially problematic for pipelines transporting gaseous fluids, where condensation is more common due to temperature differentials between the internal and external environments. By insulating the pipeline, the temperature differential is reduced, preventing condensation from forming on the surface and subsequently freezing.

In some cases, heat tracing systems can be integrated with pipeline insulation to provide a synergistic effect. Heat tracing provides the necessary heat to maintain the fluid temperature, while insulation minimizes the amount of heat lost to the environment, making the heating system more efficient. The two technologies work in tandem to create a thermally efficient pipeline that maintains a consistent temperature, preventing freezing while minimizing energy consumption.

Furthermore, insulation materials must be resistant to environmental factors such as moisture, chemicals, and UV degradation. In applications where pipelines are exposed to the elements or corrosive chemicals, using insulation materials with built-in resistance to these factors is essential to ensure the long-term durability and effectiveness of the system. For example, closed-cell foam materials are particularly effective in preventing water absorption, which can reduce thermal performance over time.

Regular maintenance and insulation inspections are also necessary to ensure that the insulation remains intact and effective throughout its service life. Over time, insulation can degrade due to physical damage, moisture intrusion, or thermal cycling. In such cases, repairs or replacements may be needed to restore optimal thermal protection. Regular inspection helps to identify hot spots or areas of excessive heat loss, allowing for targeted interventions before freezing or other issues occur.

4. Advanced Control Systems and Automation for Freeze Prevention

Advanced control systems and automation are increasingly being used to enhance the effectiveness and efficiency of pipeline heating systems in cold climates. These systems utilize a combination of sensors, actuators, intelligent algorithms, and real-time data to monitor and adjust the heating requirements of the pipeline, ensuring that the fluid temperature remains within the desired range. With automation, the need for manual intervention is minimized, and the system can respond more quickly to changing environmental conditions, reducing the risk of freezing and operational disruptions.

The core of these advanced control systems is the sensor network, which continuously monitors various parameters such as ambient temperature, pipeline temperature, flow rate, pressure, and fluid viscosity. These sensors provide real-time data that is fed into a central control unit. The control unit processes the data using sophisticated algorithms and makes automatic adjustments to the heating system, such as increasing or decreasing the heat output from electric heat trace cables, steam tracing, or other heating methods. This level of automation allows for precise temperature control, ensuring that the pipeline is never exposed to temperatures that could lead to freezing.

In addition to the basic control mechanisms, smart control systems also integrate predictive analytics to anticipate future temperature changes based on historical data, weather forecasts, and environmental patterns. For instance, if the system detects that a cold front is approaching or that temperatures are expected to drop significantly overnight, it can automatically increase the heat output in anticipation, preventing any lag in response time. This proactive approach ensures that the system is always prepared to handle sudden changes in temperature, reducing the risk of freeze damage.

These advanced systems are also capable of remote monitoring and management, allowing operators to oversee and control the heating system from a centralized location, even if the pipeline spans hundreds or thousands of miles. This is especially beneficial for pipelines in remote areas or offshore operations, where constant on-site monitoring may not be feasible. Supervisory Control and Data Acquisition (SCADA) systems are often used in conjunction with pipeline heating controls, providing operators with a comprehensive view of pipeline performance and environmental conditions in real time.

The integration of IoT (Internet of Things) devices further enhances the capabilities of these systems. IoT sensors can be installed at various points along the pipeline to monitor temperature fluctuations, detect blockages, and identify potential areas of concern. The collected data can be analyzed and used to optimize the heating process, ensuring that only the necessary amount of energy is used to maintain optimal conditions. In some cases, artificial intelligence (AI) can be employed to refine the algorithms used in temperature control, learning from past data to make more accurate predictions about future conditions.

Safety is another key aspect of automated control systems. Modern systems are designed to detect anomalies in the pipeline, such as sudden temperature drops, heater malfunctions, or electrical failures, and trigger automatic shutdowns or alerts for corrective action. This ensures that the pipeline remains safe and operational, reducing the likelihood of catastrophic failures due to freezing or equipment failure.

Energy efficiency is also a significant advantage of automated systems. By continuously adjusting the heating power based on real-time data, these systems can prevent the wasteful use of energy while still ensuring that the pipeline is adequately heated. For example, in periods of milder temperatures, the system can reduce heat output, cutting down on energy consumption without compromising the protection against freezing.

The data collected by these advanced systems can be used for predictive maintenance. By analyzing trends in the heating system's performance, operators can identify potential issues before they become critical, such as wear and tear on heating cables or steam tracing systems. Predictive maintenance allows for more efficient scheduling of repairs and replacements, minimizing downtime and extending the lifespan of the heating equipment.

5. Energy Efficiency Strategies in Pipeline Heating Systems

Energy efficiency is a critical consideration in the design and operation of pipeline heating systems, especially in cold climate environments where heating demands can be substantial and continuous. Efficient energy use not only reduces operational costs but also minimizes environmental impacts by lowering greenhouse gas emissions and conserving resources. Several strategies can be implemented to optimize the energy consumption of pipeline heaters, balancing the need for freeze prevention with sustainable practices.

First, the integration of insulation and heating systems plays a fundamental role. Proper insulation significantly reduces heat loss, which means the heating system does not need to operate at maximum capacity continuously. This synergy between insulation and heating allows for lower power consumption and more stable temperature control. For example, pipelines insulated with high-performance materials can maintain internal temperatures for longer periods without additional heating, reducing the frequency and duration of heater activation. This leads to significant energy savings over time, especially in long pipeline runs exposed to harsh environments.

Second, the adoption of self-regulating heat tracing cables improves energy efficiency. These cables adjust their heat output based on the surrounding temperature. When the environment warms up, the cable reduces power consumption, and when it cools down, it increases heat generation accordingly. This automatic adjustment prevents unnecessary energy use during milder conditions while maintaining adequate heat during colder periods. Compared to constant wattage cables, self-regulating heat trace cables provide a more economical solution by delivering heat only where and when it is needed.

Third, advanced temperature control and automation systems significantly contribute to energy efficiency. Automated systems equipped with temperature sensors, weather data inputs, and predictive algorithms allow heating elements to operate precisely in response to actual conditions rather than fixed schedules or manual controls. This precision reduces energy waste by avoiding overheating or underheating. For example, systems can preheat pipelines before temperatures drop below freezing and reduce heat once safe temperature levels are restored. Such smart control prevents continuous full-power operation, which is inefficient and costly.

Fourth, zoning and segment control enhance energy management. Instead of heating the entire pipeline uniformly, which may be unnecessary and inefficient, pipelines are divided into segments or zones based on environmental exposure, fluid type, and criticality. Each zone is heated independently, allowing for more targeted energy use. For instance, pipeline sections exposed to wind or direct cold may require more heating than those buried underground or protected by buildings. By focusing heating efforts where needed most, energy consumption is optimized.

Fifth, heat recovery and reuse systems can be incorporated into pipeline heating designs. Some pipeline systems generate waste heat from fluid friction, pumping stations, or adjacent processes. Capturing and redirecting this heat to warm the pipeline can reduce the need for additional external heating. Similarly, in industrial plants, excess steam or hot water from other operations can be channeled into heating pipelines, improving overall energy utilization and reducing operational costs.

Sixth, renewable energy sources are increasingly integrated to power pipeline heating systems. Solar panels, wind turbines, and geothermal systems can provide clean energy for electric heating cables or heat pumps. This not only lowers reliance on fossil fuels but also enhances system resilience in remote locations where grid electricity may be unreliable or expensive. Incorporating battery storage or hybrid energy solutions allows heating systems to operate continuously despite intermittent renewable energy availability.

Seventh, regular maintenance and system optimization are essential to sustaining energy efficiency. Over time, insulation materials can degrade, heating cables may develop faults, and control systems might lose calibration, all of which can increase energy consumption. Routine inspections, repairs, and upgrades ensure the heating system operates at peak efficiency. Predictive maintenance using sensor data can identify inefficiencies early and guide timely interventions.

Eighth, system design optimization from the outset affects energy efficiency profoundly. Selecting appropriate heater types, sizing heating elements correctly, and designing the pipeline route to minimize exposure to extreme conditions reduce overall heating demand. For example, burying pipelines deeper or routing them through sheltered areas can lessen heat loss and energy requirements. Similarly, choosing materials with favorable thermal properties and employing protective coatings can improve heat retention.

Operator training and energy management protocols contribute to efficient pipeline heating. Operators should understand the principles of freeze prevention and energy conservation to make informed decisions about system operation. Implementing energy audits and tracking consumption data helps identify areas for improvement and supports continuous efficiency gains.

6. Maintenance Practices to Ensure Reliability of Pipeline Heating Systems

Maintenance is a cornerstone of reliable and effective pipeline heating systems, especially in cold climates where the failure of heating equipment can lead to costly downtime, safety hazards, and environmental damage. A well-planned and executed maintenance program ensures that heating components, insulation, and control systems function correctly throughout their service life, preserving operational integrity and preventing freezing incidents.

First, regular inspection of heating elements is vital. Electric heat tracing cables, steam tracing lines, and induction heaters are subject to wear, damage, and degradation over time. Visual inspections can detect physical damage such as abrasions, cuts, or corrosion on cables and tubing. Electrical testing, including insulation resistance measurements and continuity checks, helps identify faults or shorts that could impair heater performance. In steam tracing systems, leak detection and pressure tests verify the integrity of the steam supply and condensate return lines, preventing steam loss and ensuring consistent heating.

Second, insulation condition assessments are crucial. Insulation materials may degrade due to weather exposure, mechanical impact, moisture ingress, or chemical attack. Periodic thermal imaging inspections help detect insulation defects, heat loss points, and wet spots that reduce thermal efficiency. Moisture penetration is particularly detrimental because it lowers the insulation's R-value and accelerates corrosion of the underlying pipe. Repair or replacement of damaged insulation sections maintains heat retention and protects pipeline components.

Third, control system calibration and software updates support accurate temperature regulation and energy management. Sensors, thermostats, and control units must be calibrated regularly to ensure correct readings and responses. Software updates can enhance algorithm performance, add new features, or address security vulnerabilities. Automation systems relying on outdated or malfunctioning components may cause overheating, underheating, or unplanned shutdowns, compromising pipeline safety.

Fourth, cleaning and mechanical upkeep of heating components reduce performance issues. In steam tracing, removing condensate buildup and scaling in lines ensures efficient heat transfer. Similarly, cleaning electric heater surfaces prevents dirt accumulation that can insulate heating elements and impair heat conduction. Mechanical fastening systems, brackets, and supports must be checked for corrosion or looseness to prevent damage from vibration or thermal expansion.

Fifth, emergency response protocols for heating system failures should be established. In cold climates, rapid action is needed to restore heating or implement temporary freeze protection measures. Spare parts inventory, backup power supplies, and contingency plans minimize downtime and damage. Staff training in emergency repairs and diagnostics enhances readiness.

Sixth, documentation and record-keeping improve maintenance effectiveness. Keeping detailed logs of inspections, repairs, component replacements, and performance data helps identify recurring issues and guides long-term improvement. Data analysis supports predictive maintenance strategies that anticipate failures before they occur, reducing unplanned outages.

Seventh, collaboration with manufacturers and service providers ensures access to technical expertise and updated maintenance practices. Manufacturer recommendations for servicing intervals, approved repair techniques, and warranty conditions provide valuable guidance. Periodic audits by third-party experts can validate maintenance quality and compliance with industry standards.

Eighth, environmental considerations must be integrated into maintenance activities. Proper disposal of damaged insulation materials, chemicals, and electronic components avoids environmental contamination. Maintenance schedules should also consider weather conditions to avoid unsafe working environments or further system damage during storms or extreme cold.

Ongoing training and professional development of maintenance personnel keep skills current with evolving technologies. As pipeline heating systems incorporate advanced controls, IoT integration, and novel materials, technicians require continuous education to manage and troubleshoot these complexities effectively.

7. Integration of Renewable Energy Sources in Pipeline Heating Systems

The integration of renewable energy sources into pipeline heating systems represents a growing trend driven by the need to reduce carbon footprints, lower operational costs, and improve sustainability in cold climate operations. Traditional heating methods, such as electric resistance heaters or steam tracing, often rely on fossil fuels or grid electricity, which may be costly, subject to supply disruptions, or environmentally unfriendly. Incorporating renewable energy technologies into pipeline heating infrastructure offers an innovative approach to maintaining optimal fluid temperatures while addressing environmental and economic challenges.

One major advantage of renewable energy integration is the reduction in greenhouse gas emissions associated with pipeline heating. Cold climate operations typically demand continuous or frequent heating to prevent fluid freezing, which leads to significant energy consumption. By substituting or supplementing fossil-fuel-based energy with solar, wind, geothermal, or biomass energy, operators can substantially decrease the carbon emissions tied to freeze prevention efforts, aligning pipeline operations with global sustainability goals and regulatory requirements.

Solar energy is one of the most accessible and widely used renewable sources for pipeline heating. Solar panels can be installed at pipeline facilities or along pipeline routes, converting sunlight into electrical power that feeds heating elements such as electric heat tracing cables. In regions with high solar insolation even during winter months, solar energy can cover a substantial portion of the heating demand. Coupled with battery storage systems, solar-powered heating can provide reliable temperature maintenance during night-time or overcast conditions. Solar thermal collectors can capture sunlight directly as heat, which can then be transferred to pipelines through fluid loops or heat exchangers, reducing dependence on electric heating.

Wind energy is another promising renewable source, especially in cold climates where windy conditions are frequent. Small-to medium-scale wind turbines can be deployed near pipeline sites or compressor stations to generate electricity for heating systems. The intermittent nature of wind requires integration with energy storage or backup power sources to maintain consistent pipeline temperatures. Advances in wind power technology, including improved turbine designs and predictive maintenance, have enhanced the reliability and cost-effectiveness of wind energy in remote and harsh environments.

Geothermal energy offers a stable and continuous heat source that can be harnessed for pipeline heating. By tapping into subsurface heat reservoirs, geothermal heat pumps or direct-use geothermal systems can supply heat to pipeline circuits without reliance on external fuel sources. Geothermal energy is particularly advantageous for buried pipelines or facilities located near geothermal hotspots, providing consistent thermal energy regardless of surface weather conditions. However, initial investment costs and site-specific geological factors can influence the feasibility of geothermal integration.

Biomass energy, derived from organic materials such as wood chips, agricultural residues, or specially grown energy crops, can be utilized to generate heat for pipeline heating. Biomass boilers or combined heat and power (CHP) plants can produce steam or hot water used in steam tracing systems. The renewable nature of biomass and its potential for carbon neutrality make it an attractive option in areas with abundant biomass resources. Nonetheless, logistics related to biomass supply, storage, and combustion emissions require careful management.

Hybrid renewable energy systems combine multiple sources to improve reliability and efficiency. For instance, a system combining solar and wind energy with battery storage can offset the intermittency of each source, ensuring steady power availability for pipeline heating. Hybrid configurations can also integrate renewable sources with conventional backup heating systems to guarantee freeze protection during extreme cold snaps or periods of low renewable generation.

Integration of renewables demands a comprehensive energy management system capable of balancing energy supply and demand dynamically. Smart grid technologies, coupled with IoT sensors and automation, allow real-time monitoring of energy production and consumption, optimizing heating system performance. Predictive analytics can forecast weather conditions and energy availability, enabling preemptive adjustments to heating operations. For example, if solar power generation is expected to drop, the system can switch to stored energy or backup sources without compromising pipeline temperature.

Challenges in renewable integration include the need for initial capital investment, site-specific feasibility analysis, and ensuring system reliability. Renewable energy systems often require higher upfront costs compared to traditional heating methods, although long-term operational savings can offset this. Site assessments consider factors such as solar exposure, wind patterns, geothermal resource availability, and biomass supply chains to determine the best renewable options. Maintaining consistent pipeline temperatures in critical operations requires robust system design incorporating redundancies and backup power to handle renewable intermittency.

Regulatory frameworks and incentives also influence renewable energy adoption in pipeline heating. Governments may provide subsidies, tax credits, or carbon pricing mechanisms that improve the economic viability of renewable projects. Compliance with environmental standards encourages operators to adopt cleaner energy sources, enhancing corporate responsibility and public perception.

The integration of renewable energy sources into pipeline heating systems offers numerous benefits, including reduced emissions, operational cost savings, and enhanced sustainability. Advances in solar, wind, geothermal, and biomass technologies, combined with smart energy management and hybrid configurations, enable effective freeze prevention in cold climates while aligning with global environmental goals. Careful planning, investment, and system design are essential to maximize the potential of renewable energy in pipeline heating applications.

8. Safety Considerations and Regulatory Compliance in Pipeline Heating

Safety and regulatory compliance are paramount concerns in the design, operation, and maintenance of pipeline heating systems, particularly in cold climate operations where failure to prevent freezing can result in catastrophic consequences. Pipeline heating involves electrical, thermal, and mechanical components that must adhere to stringent safety standards to protect personnel, the environment, and infrastructure integrity. Furthermore, regulatory frameworks at local, national, and international levels impose requirements to ensure safe and environmentally responsible pipeline operations.

One of the primary safety considerations is electrical safety for heat tracing and heating cable systems. Electric heat tracing involves high voltages and currents that pose risks of electric shock, short circuits, and fire hazards if not properly installed and maintained. Compliance with electrical codes and standards such as the National Electrical Code (NEC) in the United States, IEC standards internationally, and industry-specific guidelines is mandatory. Proper grounding, circuit protection devices, and installation practices minimize risks. Heat tracing cables must be selected and installed according to their rated voltage, temperature class, and environmental conditions to avoid overheating or insulation failure.

Thermal safety is another critical factor. Overheating of pipelines can lead to damage to pipe materials, degradation of transported fluids, or ignition of nearby combustible materials. Control systems must incorporate fail-safe mechanisms such as temperature limiters and automatic shutdowns to prevent excessive heat application. Steam tracing systems require pressure relief valves and condensate removal to prevent overpressure and maintain system integrity. Operators should be trained in recognizing thermal hazards and responding promptly to temperature anomalies.

Mechanical safety pertains to the structural integrity of heating components and pipeline supports. Expansion and contraction caused by thermal cycling can stress pipes, insulation, and mounting hardware. Designs must accommodate thermal expansion to avoid mechanical failure or dislodgment of heating elements. Regular inspection for corrosion, vibration damage, and mechanical wear ensures continued safe operation.

Another significant safety concern involves environmental hazards associated with pipeline heating systems. For example, steam tracing may involve high-pressure steam that poses burn risks or potential leaks of hazardous substances. Electrical systems must be protected from moisture ingress and explosive atmospheres in hazardous locations, requiring explosion-proof equipment and appropriate certifications. Proper insulation materials must be fire-resistant and comply with environmental regulations on chemical content and disposal.

Regulatory compliance extends beyond safety to encompass environmental protection and operational standards. Agencies such as the U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA), the Canadian Energy Regulator (CER), and the European Union’s Pressure Equipment Directive (PED) enforce rules on pipeline heating design, installation, inspection, and documentation. Operators must maintain detailed records demonstrating compliance with maintenance schedules, equipment specifications, and incident reporting.

Environmental regulations also address emissions and waste management related to pipeline heating. For instance, steam tracing systems powered by fossil fuels contribute to greenhouse gas emissions, and operators may be subject to emission limits or carbon pricing. Disposal of insulation materials, damaged cables, or chemical residues must follow hazardous waste protocols to prevent soil and water contamination. Compliance with environmental laws ensures responsible stewardship and community safety.

Personnel safety training is essential in managing risks associated with pipeline heating. Workers must be knowledgeable about electrical hazards, thermal burns, confined space entry, and emergency response procedures. Training programs should cover the proper use of personal protective equipment (PPE), lockout/tagout procedures for electrical isolation, and safe handling of steam and heating fluids. Regular safety drills and audits promote a culture of safety and preparedness.

The design phase of pipeline heating systems must incorporate safety and compliance considerations from the outset. Risk assessments identify potential hazards, allowing engineers to implement mitigations such as redundant controls, protective barriers, and emergency shutdown capabilities. Selection of certified equipment and adherence to recognized standards reduce liability and enhance reliability.

Emerging technologies also contribute to improved safety and compliance. Remote monitoring and diagnostics enable early detection of faults, overheating, or electrical anomalies, allowing proactive interventions before incidents occur. Automated reporting and documentation tools assist operators in meeting regulatory requirements and maintaining transparency.

Looking For Business Opportunity?

Request for a call today

WhatsApp: +86-185-5601-8866

Tel: +86-185-5601-8866

E-mail: [email protected]

Address: Sinton Building, No. 886 Yandu Road, Yandu District, Yancheng City, Jiangsu Province

Friendly Link: www.cn-lvdao.com www.sealing-china.com

Products

Message